R1100S and RT and GS Turbo Systems

We go to Bonneville to test things. At the World Finals in October 2009 we were racing our 139" Bonneville Bullett so we decided to make a test ride on the RT Turbo by doing a round trip from LA to the Salt Flats going up through the middle of Nevada where the altitudes reached over 7000 feet and the temperatures were decidedly chilly. No issues, the bike ran fine, getting 40 mpg with some 150 mph cruising. Nothing out-accelerated it.

We don't recommend flying past past semis at 150 mph as the wind blast gets a bit interesting.

If you'd like to see how you install one of these we provide a generalized installation guide. We keep a number of these in stock in a semi-finished state and they are finished in Black or Silver. Delivery is 30 days ARO.

Ultimate Touring Bike?

A 2000 R1100RT Turbo that can outrun a Hayabusa and drive to Alkaska with saddlebags. It's a product of a long development involving constant refinement and a large dose of fabrication skills and electronics expertise. To take a lowly 80 or so horsepower RT and turn it into a 9 second 160 mph rocketship that will still get more than 40 mpg is no small feat. In our case it takes about 30 years of turbo experience to pull it off.

We turbocharged one of the first R1100RS twins back in 1993. How time flies. An interesting journey. This is newer design and improved technology. This one belongs to us and we've been running it for over a year of constant testing. It does get expensive paying employees to test things and all the expenses that go with such a project, but we only do things one way..Either "our way" or the "right way" depending on how you look at it. If you have the money you can get one.

Holy Batman! An "S" With Power

Poor R1100S, a lousy 86 rear wheel hp, and a tail-mounted, wannbee Ducati, license plate warming muffler. Twin plug, single plug, "Replica" paint, carbon fiber bits etc....All foo, foo, crap for a bike with no power. When they say it's not about the money...It's about the money. When you haven't got the power...It's still about the power.

RB Racing gives you a power correction with 240 hp worth of an intercooled, water injected turbo. For you incremental types, you can dial down the power to a manageable 135 hp and keep your fear factor in check. Hey, it's still got a shaft drive so you won't be running 220mph! We like to run way over 200 but not everyone does.

Front mounted Boost Master wastegate controlled by a handlebar mounted pneumatic boost controller. Dial up your courage. Ceramic coated merge collector turbo header has dual egt ports for our manadatory Orca Turbo Dash.

Charge cooler sheds heat and breaks up directional flow from turbocharger. Downstream are four injectors and two water injection nozzles. New electronics control the fuel and water injection.

No one is going to see the turbo as it's under the bike. All anyone will see is the end of your tail pipe anyway...Unless you just like to park and talk and bask in the glory of your new toy.

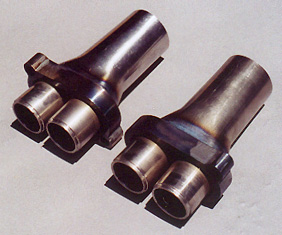

Turbo Dump Pipe

Instead of our Black Hole Muffler tail section we also make a R11 series turbo dump pipe for racing. This provides less restriction and higher performance . We use simple dump pipes on all our turbo race bikes. Chrome, Black Ceramic or Silver Ceramic finishes. Extra cost option if you are going to race your bike.

The Jig is Up!

This is most of the fixtures required to make a R11 Turbo kit. Actually there are about twice this many, not including the cnc machining setups that we use. Figure that we redesigned this kit six times from 1994 to present you could throw away about five piles of steel this large...not to mention barrels full of parts we sent to the scrap heap. Don't ask how much money we spent because it is way too painful to think about.

Raw Parts

Takes a lot of fixtures and sub fixtures to make this part accurately. Don't ask us to buy one as it is only sold with the kit. You don't want to know what it costs in final form factoring in shop time, wages and administrative matters like coating, laser cutting, welding supplies, employee training etc. It is dead accurate when we finish.

High Stakes

You're sitting at the Baccarat table in Wendover keeping your steely eyes on the Mormons who've sneaked over from Salt Lake to be naughty, and those Bonneville groupies who are eyeing your pile of chips see a good time coming. Push that pile of water jet cut copper gaskets out and bet the farm. It's your lucky night. That's $1,000.00 in copper turbo gaskets. It does get expensive. Before they are shipped they get annealed to make them soft.

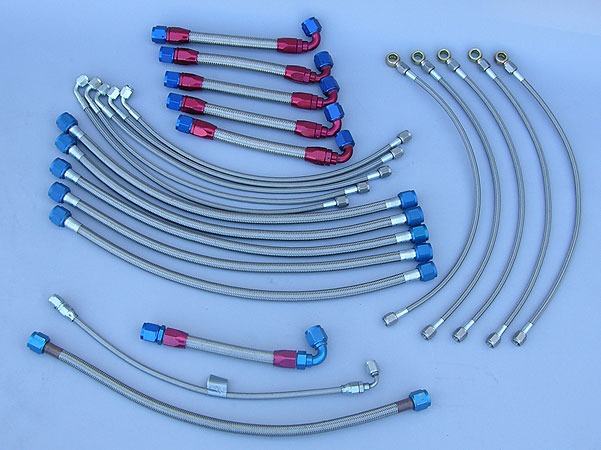

More $1,000.00 Days

Customers just think we just stop whatever we are doing and go build them a turbo system for their R Bike. It doesn't work that way. Oil systems are particularly ornery and chew up months of development in prototyping and then even more time in the refinement and testing phases. At that point you get to take your sample parts to your hose fabricator and hand over a four digit pile of your hard earned dollars just so you can have some parts in stock. And there are a lot more parts in a turbo system.

Some More Parts

These are a few of the parts that are in a BMW R1100RT Turbo Kit. Just a few. Bending , fabrication, ceramic coating, cnc machining, laser cutting, and many hours of tig welding. Procedures, documentation, training....tens of thousands of dollars tied up so we can go fast. Of course, if you sit in a cubicle, and order parts from China for Walmart you have little appreciation for this.

R1100/1150 Intercooler

Well, you start with 20 pieces of aluminum. Cut, machine and otherwise make them into some specific shape. Then you start welding. You best keep cut patterns, sample parts and notes or you will not be able to duplicate it again. We make a prototype like the one below, test it over several thousand miles and if everything is OK we go into limited production. A lot of hours and quite expensive.

Gets complicated. Holes for injectors, holes for water injection, holes for injector hold downs. Cut, weld, debur, heliarc, machine, drill, tap...it never ends. We tested this prototype for several thousand miles.

Polish, Ceramic Clear Coat

Production R1100/1150 Intercoolers. To prevent corrosion we polish the intercoolers and bake on a high temperature ceramic clear coat. Expensive and labor intensive process, but they stay looking this way.

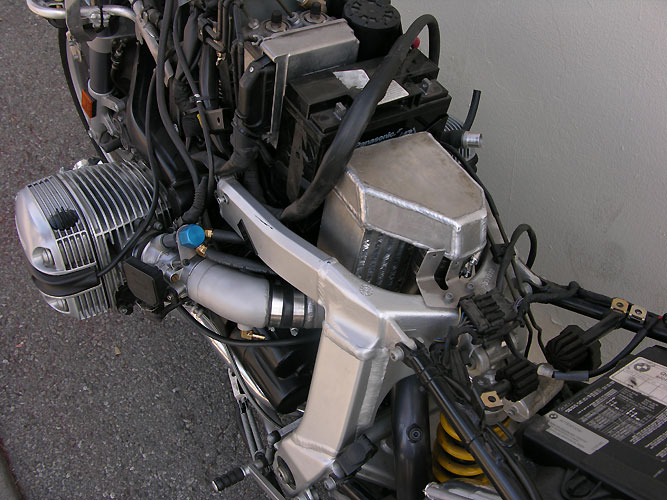

RT Ducting

On the R1100/1150RT the original inlet duct is retained to direct air beneath the bodywork to the intercooler. We tie wrap the duct exit to the frame rail. Pneumatic boost only lines are visible in the picture which are used for water injection activation and other electronic controls. A total of four injectors are used to control the fuel delivery from 30" Hg to 30 psi.

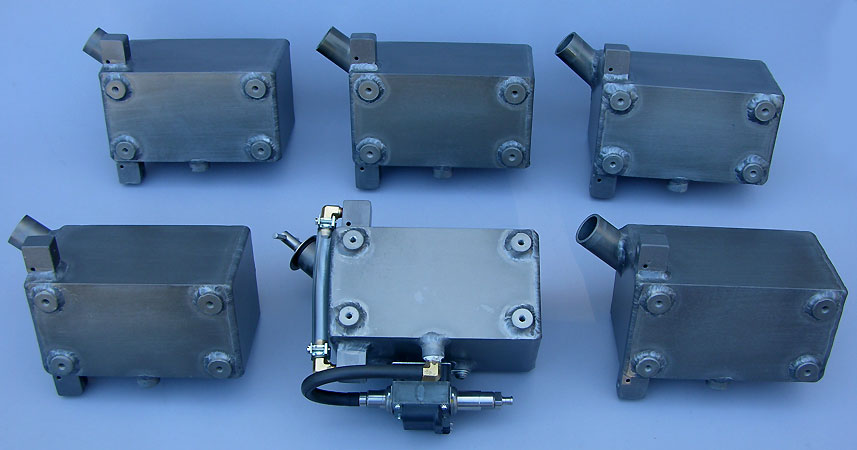

Water Injection

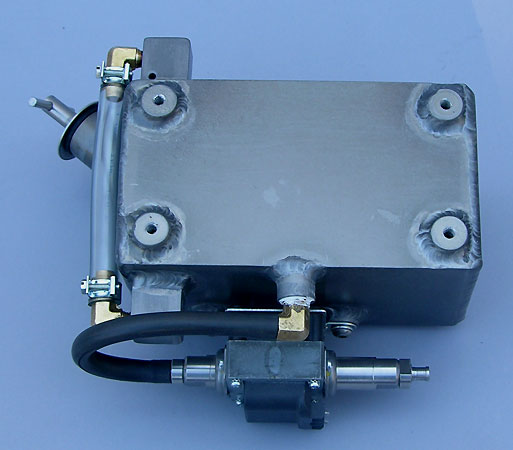

Water injection is mandatory on all BMW turbocharger kits. We make an aluminum water reservoir that fits in the license plate location. Here it is trial fitted to a R1100RT and a R1100S prior to being hard anodized. A clear hose is used as a sight window to check water level. Capacity is slightly above one quart. On R1100/1150 turbo kits the water is injected into a common area, in the intercooler, between each inlet runner. Two water nozzles are used and are staged for low and high boost levels.. It is completely pre-planned and there are no adjustments to make. The RSR Pro-440 230 psi pump mounts on base of reservoir.

Hard anodized water injection reservoirs for our turbo kits. Lots of cutting, deburring, cleaning, welding, and machining to get these ready. Lathes, mills, heliarc, large buffers, drills, taps and employees. Money, money, money....Accountants cringe. The IRS doesn't believe you spend all that money on R&D until they audit you.

License plate mounted. Integral 230 psi pump assembly. Stainless steel hardware. Level sight window. Quick release stainless steel filler plug. Hard anodized for water and water alcohol or water methanol corrosion resistance. Whatever it takes. We know what it takes. Wannabes and Wannaknows whine endlessly. Wannabuys buy. Someone goes fast.

Dual stage water injection. Solenoids mounted on powder coated support bracket for BMW R1100/1150RT. Endless details for trouble free performance.

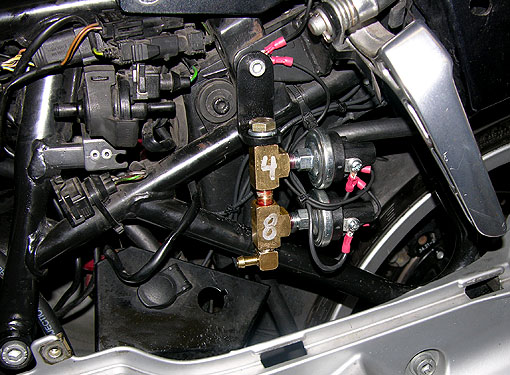

Dual stage water injection pressure switches. Primary nozzle activates at 4 psi and the secondary joins in at 8 psi when things get serious. R1100/1150RT beneath left panel. Relays for these are secreted into the oem fuse box. Switches only see boost, not vacuum/boost.

Rocket Fuel

When Honda was spending 500 millions dollars a year on their V6 Formula 1 Turbo motors they ran a mixture containing 84% Toluene (114 Octane). It has excellent anti-detonation properties and increases your octane rating. If you are running 92 octane pump gasoline and you add this stuff, your octane rating will be changed by the formula:

[(Quarts Gas x 92) + (Quarts Toluene x 114)] / (Quarts Gasoline + Quarts Toluene).

For example, if you add one quart Toluene to four gallons of gasoline, your Octane will increase onr point from 92 to 93. Add two quarts to four gallons and you get an Octane rating of 100. For you high boost junkies this is something to ponder. You can buy the product in hardware stores. Xylene has a higher flashpoint (less volatile) and has and octane rating of 117.

Denatured alcohol or methanol can be added in a 50/50 mix in our water injection systems.

RT Testing

Say you work for RB Racing. Say you get paid to ride around Califonia and test 200 hp Turbo bikes. It gets tiring so, every so often, you need to take a break, make a few notes, have some lunch, hit the usual spots, and visit a few friends. Do some extended cruising at 110 mph and watch the speedo head past 140 mph. All in a days work. We work hard. We play hard. If it's not fun we don't do it. iPhone3Gs photo during testing.

We always run our initial instrumented tests without the muffler so we can watch the exhaust turbine wheel. When we finish several thousand miles of testing at different altitudes, temperatures we put on the muffled tail section and quiet the thing down to a whisper. We also make a short dump pipe for racing.

RT Muffled

Once the bodywork is on you can't see any turbo equipment, hoses etc. Bike has a nice tone with our low restriction Black Hole Muffler. Accelerating to 158 mph does not draw attention. Not stock quiet. We would not do that.

2 cyl...Homeboy 133hp

About 100 hp short of one of our turbos this HP2 Sport with DOHC is an expensive toy. For those who worship exclusivity it is a nice addition to their collection. Still too slow for our tastes.

4 cyl..Yardstick

In case you are wondering...It is damn fast. Our test rider has more than one million miles of road work and has ridden lots of high end turbo drag bikes. He knows how fast it is. Is it faster than a Hayabusa? So far it is, running 15 psi of boost through the top of third and fourth gears past 145 mph where the Busa was way back in the rear view mirrors.

4 cyl..Homeboy

S1000RR, 193 hp of 600 Sportbike sized crotch rocket with clip-ons. No saddle bags, no passenger, no windshield, no 33 liter top case, no radio and less horsepower than our R1100RT Turbo. BMW joins the fray with Hayabusas, GSXRs, Yamaha R1s, and CBRs. Race track, not touring, is the intent. Not the bike for a cross country jaunt but great for park and talk one-upsmanship... At least until the next great thing arrives.

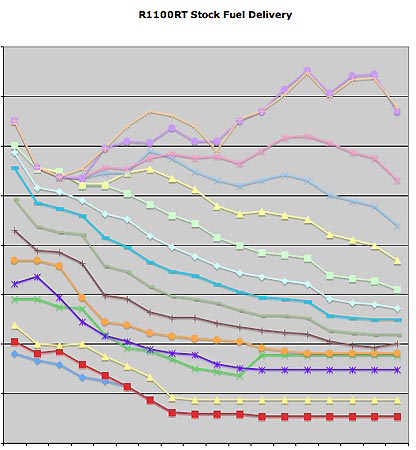

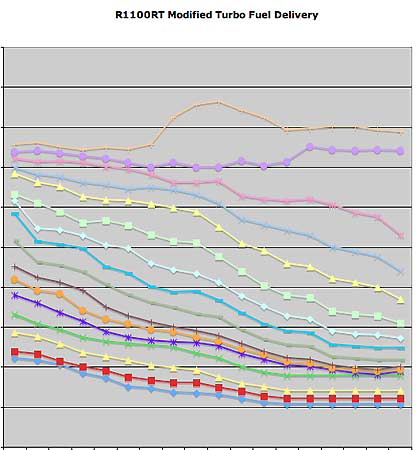

RSR AIC400 Additional Injector Controller

We preprogram the fuel curve for the two additional injectors with our RSR AIC400. About 2000 points to program. We do it for you. AIC400 mounted on R1100RT. User adjustable on the fly with four fuel maps and a +/- 10% trim knob to account for extreme altitude variations. The bike is closed loop but we electronically put the bike into open loop under AIC400 fuel control under certain boost conditions. You can cruise the bike at 100 mph on the edge of boost or cruise at 135 mph under closed loop control....or you can run 200hp under AIC control. No one said this was easy.

More Zeros and Ones...Motronic Magic

![]()

Take a R1100RT with a 10.7:1 compression ratio or a R1100S with 11.3:1 compression, add 15 pounds of boost and a completely stock ecu and you get an explosive combination leading to detonation and preignition. Even with enough camshaft overlap to breathe at 8200 rpm you are heading to Pro Stock type effective compression ratios...and you're running pump gas.

The Motronic 2.2 is a N-Alpha system which is a Throttle Angle/RPM based system which is calibrated for emissions purposes i.e. they will lean out the mixtures and fool with the timing to get the best emission results. You end up with "fuel maps" that are a bit strange. In closed loop operation the Motronic generally adds fuel all the time except for wide open throttle and cold start operation. Put on a very efficient turbocharger and increase the airflow and torque and the Motronic can't add enough fuel. We get to rewrite this stuff as BMW did not design the maps for as much air as we pump through the system.

For our BMW turbos we found out 15 years ago that we had to rewrite the Motronic calibrations for fuel delivery, ignition timing and rpm limits. It is so much fun taking apart ecus, poking around in a sea of hexidecimal code, one step above the binary world of zeros and ones, especially when you get to plug, unplug, dyno things, ride things and wrestle with the complexity of BMW fasteners.... 3mm, 4mm, 6mm, and tamper proof Torx.

Our R series turbos have revised ecu calibrations for optimal turbo performance. Calibrating N-Alpha (throttle angle based) Motronic code to work with Speed Density (pressure based) RSR AIC400 controllers requires a bit of thought. Over 30 years of racing sort of helps. We revise the ignition timing and factory rev limts.

In case you want to know how much all this stuff does try 158 mph in 5th gear on a 100 Deg F day with 7 pounds of boost @9000 rpm. Regeared we will run the RT out to 187 mph and, it does get to the self-imposed limit at 158 mph very quickly.

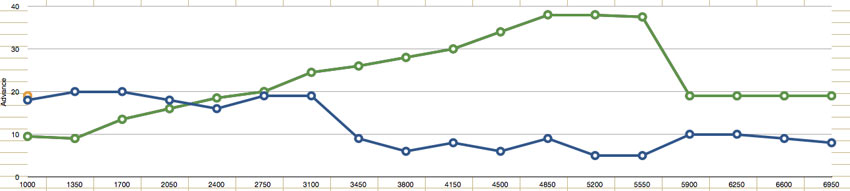

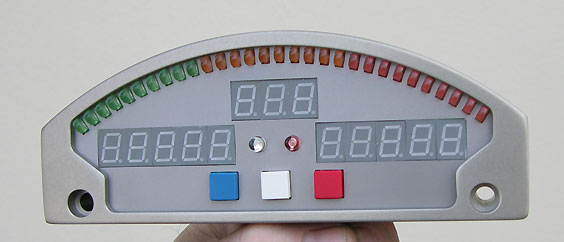

Turbo Dash...Ultimate Instrumentation for the Turbo

Water injection activation is indicated on our Orca Turbo Dash. 30 L.E.D.s display 30" Hg to 30 psi of boost (3 Bar). Three digits display manifold pressure in Bar, 0.00 to 3.00. Two type K fast-acting thermocouples read exhaust gas temperature in left and right cylinders. Three buttons: high recall from memory (blue); display dimming (white); and reset (red) to clear memory. Two additional green L.E.D.s indicate the two stage water injection system. Mandatory on all BMW turbo kits.

This is the location of the billet Orca Turbo Dash on the R1100/1150RT. Direct line of sight whether racing or just touring. We race. We race when we tour.

Key on with atmospheric pressure we are showing 1.02 Bar Manifold pressure. Engine has not been run, so thermocouples are reading ambient in each primary tube of 80 Deg F. RSR Air Fuel Ratio Gauge has red light illuminated showing there is no oil pressure. Orca Turbo Dash is in line sight so you do not take your eyes off the road. In full crouch racing position you look directly above the display.

Two round green L.E.D.s at center of the display indicate dual stage water injection activation. Rightmost round L.E.D. is primary stage activation and leftmost is secondary stage activation of water injection. The purpose of the H2O is not to drop the egts as temperature is power... It is simply to increase charge density and forestall detonation. When fully warmed and idling under closed loop operation we will see about 1000 Deg F.

Under closed loop cruise we show 1370F and at full 12 psi and about 185 hp @9000 rpm we show 1500F, still very safe. Does your RT stand up straight on the rear wheel in 3rd gear? This one does. Three hundred mile loops including boosted operation to 158 mph returned 41 mpg. We do thousands of miles of testing.

Boost temperature above or below desired levels can be countered by manually increasing secondary injectors +/- 10% with the knob on the RSR AIC400. Four fuel maps are provided, user selectable. Regeared we will run the bike up to 187 mph.