|

||

Coating Technology

Run with the Big Dogs...401 mph 4 cyl...436 mph 8 cylinder

Where do you go when you need technical coating advice and service? Well it might be a good idea to go where we go...But what the hell, we're just idiot motorcycle types, what do we know? The big dogs like Edelbrock, Magnuson Superchargers, Kenny Duttweiler, and about everyone in the Southern California Hot Rod industry goes to Alan at Xtreme Performance Heat Coatings to get their polishing and coating work done. Alan also runs a polishing shop and does powder coating.

The Speed Demon Bonneville streamliner with it's huge intercooler and large stainless steel fuel and water tanks were polished and coated by Alan. He ceramic clear coats the polished aluminum parts. All exhaust manifolding got ceramic heat barrier coating. The "big dogs" get their work done there. Turbonetics, Paxton, Whipple, Nuespeed, Weiand, Vortex....Big Dogs.

World's Fastest Coatings

When your plans are to go 400 mph with a 4 cylinder engine, and you have thousands of hours of custom fabrication, you better trust the people coating and polishing your parts. No one loses your parts, fills them full of polishing compound, or delays your racing effort. In the case of our own Bonneville efforts, we trust Xtreme. Kenny Duttweiler does. Liquid Nitrogen!!!!!

In 2009 the Demon ran 401 mph with the 4 cylinder engine and 436 mph with the 8 cylinder engine.

Know Who's Got Your Parts

Alan at Xtreme Performance Heat Coatings is the man to trust with your parts. He coats $8,000.00 Indy Car Inconel headers, like the one Alan is holding, and all our pesky high dollar Bonneville parts. If you who have trouble color coordinating shirts and pants, Alan will show you, left to right: Gloss Black (collector), Cermakrome, Matte Black, Grey Ice, Brushed Stainless. When high dollar mission critical parts (think of those nasty places far, far, away) need to get done, they end up getting trusted to Alan. Know who has your parts.

Restoration or Custom

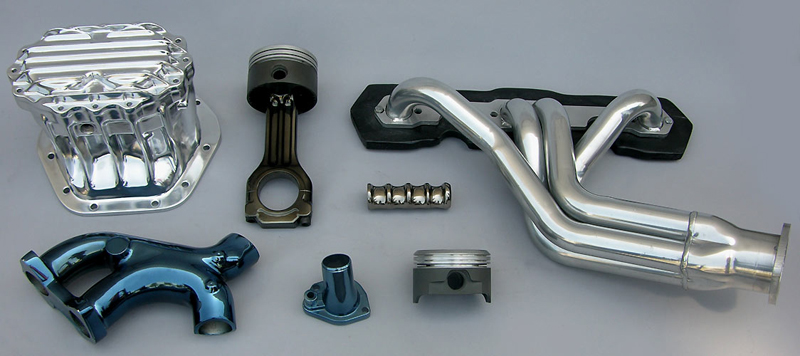

Examples: Polished and clear ceramic coated rear end; (2) Skirt coated piston; (3) Deep Cobalt Blue coated aluminum parts;(4) Racing piston with skirt coating and a heat barrier coating on dome; (5) Black Chrome coated shift handle; (6) Silver Ceramic coated header. Alan also coats Ducati parts, MV Augusta parts, Harley-Davidson parts and does restoration finishing on cars and motorcycles. He routinely powder coats motorcycle frames for high end customs and simple restorations...even old Bultacos. Matadors, Sherpas, Alpinas, Metrallas...are you old enough to know what these are? They are getting more valuable.

"Hot Bike"

"Hot Bike" used to mean it was a go fast scooter. These days it means 295 degree oil temperatures and an uncomfortable ride. Xtreme has heat barrier and heat dispersant coatings for exhausts, cylinders, cylinder heads, and engine cases that cool down things to an acceptable level. When the Harley-Davidson Evos came out in the mid 80's people were alarmed at 210 Deg F Oil temperatures...They shouldn't have been because that's where they ran best. Putting on a oil cooler to drop things below 200 Deg F just caused you to use more fuel.

These days the "modern" Twin Cam engines under computer control are running nearly 300 Deg F Oil temperatures and the computer is shutting down cylinders like Delphi did on the Cadillac Northstar V8's. Wrong! You need to get oil temperatures under control to prevent a drop in oil pressure and to keep from frying yourself in the process.

Xtreme can reduce radiant temperatures over 100 Deg F with barrier coatings and disperse heat better so it doesn't build up in the first place. Call Xtreme to see what's involved. 1-805 485-2667. We use dispersant and barrier coatings on engine parts and exhaust parts on our Turbo systems. Get an oil cooler to boot.

People all over the country send in their old iron exhaust manifolds for thermal barrier coatings. Old is in. Rusty old is out.

Fonz

Happy Days television show Fonz Triumph used by Henry Winkler. Alan is restoring it. Henry Winkler used to warm the seat in front of a projected backdrop.

139" ORCA Bonneville Pistons.

After we completed our fabrication of the watercooled Bonneville Bullett cylinders, and finish honed the bores to the exact clearances required, we had Alan coat the piston skirts of the CP Pistons and put a thermal barrier coating on the piston dome. Yes, we know it works or we would not have done it. You're 1000 miles away from your shop. It has to be right.

Teardown...Post World Finals

139" ORCA: Nine trips down the course in 2008/2009 to get bike sorted out and qualified for long course, then it was time to tear the engine and transmission down to ground zero in preparation for 2010. You don't let it stay buttoned up until next August/September/October. The engine was in fine shape and we only elected to put in new rings. The Xtreme Performance ceramic coated piston tops showed we had no detonation, deformation or burned heat patterns under the dome. Piston pit fit was as installed. There were no marks on the bore or the skirts. A very slight brush of the bores and new rings was all that was required. Carl Pelletier of Competition Motorcycles in Boise handled the initial engine build and the teardown in his race engine shop.

Complete disassembly and rustproofing and refinishing is required of any machine that goes to Bonneville. If you don't, you will drive a two thousand miles to find out that you should have.

Dicronite

Dicronite Precision Dry Film Lubricant is an interesting process that we started using in the early 1980's. We even had some shock absorber shafts coated for Roger Penske when he went into the racing shock absorber business. Reduces friction and is esentially a non-dimensional changing process suitable from -188C to +538C. Worth looking into. We got into using it because early racing Porsche transmissions got treated with the process. It is still used in racing transmissions, crankshafts and valvetrain applications at the highest level.

DLC (Diamond Like Carbon) Coatings

When you head into the cost is no object forms of racing like NASCAR and Formula 1 DLC coatings get the nod to reduce friction in areas like valvetrain components such as the tappets pictured above. If people use the process they aren't going to tell you. Diamond transfers heat faster than any other substance.