RB Racing Intercoolers

Charge Cooling

RB Racing has been turbocharging vehicles since 1979 but is only since 1985 that we have employed charge air cooling, or is more commonly referred to as "intercooling", as prior to 1985 most of our applications involved draw through carburetion which precluded the use of intercoolers. For those of you who are new to intercooling you do not blow an air/fuel mixture through an intercooler because; (a) It's not safe to have an explosive mixture in an enclosed vessel and; (b) Intercoolers were meant to flow dry, not wet mixtures.

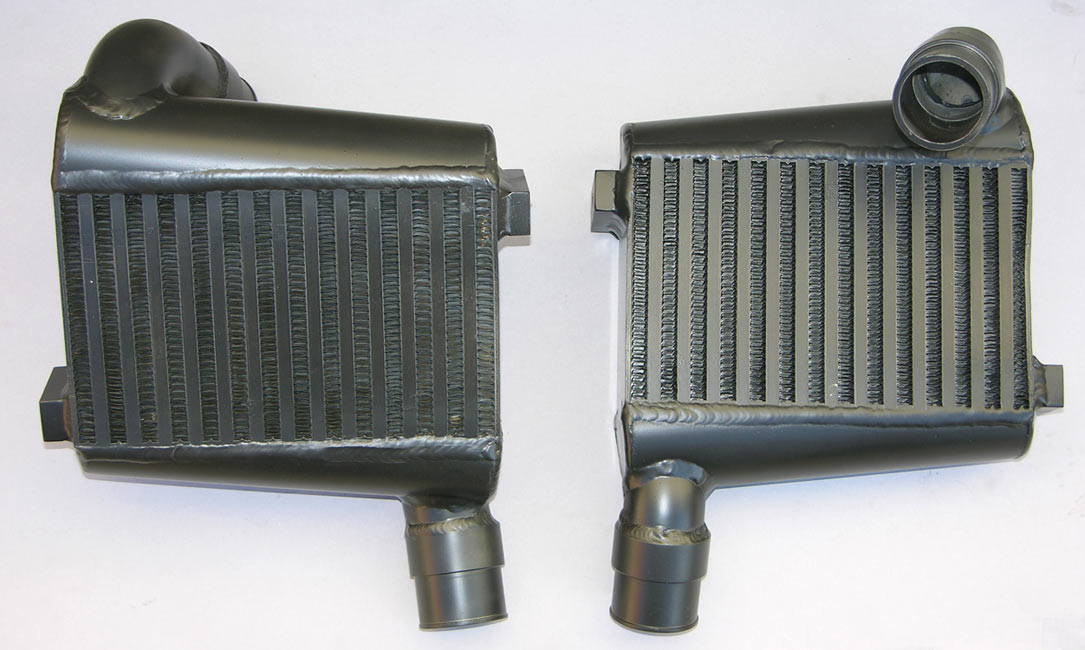

RSR Intercooler Cores

Intercoolers

are manufactured in one of two ways: Stacked Plate or Tube

construction. All RB Racing intercoolers are of the Stacked

Plate style

of construction. To simplify this choice: (a) Stacked Plate

designs are

more efficient, heavier, sturdier; (b) Tube designs are less

efficient,

lighter, less sturdy. As they say "two out of three ain't bad"

so we go

with the stacked plate design.

Design

considerations: Airflow needs to be considered in the

construction of

the intercooler inlet and outlets. Keep distances short.

Minimize

bends. Taper the hats downward from point of entry i.e. if you

blow

into one edge of the core taper the hat down to the other end

and if

you blow into the center taper it to both ends.

Don't construct hats so

some passages are partially blocked because there aren't that

many of

them.

Calculating Intercooler Efficiency

To see what the effect of boost pressure, ambient temperature, and intercooler efficiency is on the temperature of the air entering your motor we have written up the following calculator. Simply enter the three variables and the calculator will display the results in a new pop-up window.