RB Racing Turbos...Big Twins:

Shovels

Evos

Twin Cams

M8's

M8 Turbos

Twin Cam

Turbos

Evolution Turbos

Shovelhead

Turbos

V-Rod Turbo

Click

on image or text above for your motor. Scroll below for a

bit of fabrication examples.

RB Racing 45+ Years

First successful draw

through Shovelhead designs in 1980,. The first successful blow

though Evolution designs in 1985. The first intercooled

fuel injected Harleys. Developed in house PC Programmable

RSR-EFI designs in 1989. Four injector staged systems in

1990's. 2008 Water-Cooled EVO Bonneville motor 200 mph.

Bonneville World Records in 1997-2011. Digital EGT and Boost

displays. Pro Gas Drag Racing Championship with 7 second

quarter mile times @ 176mph. 2008: 1000 psi water injection

systems. 2012: Full motorsport ecus controlling boost,

traction control and fly by wire. Full mil-spec Raychem Tefzel

/ DR-25 wiring harnesses with Autosport connectors.

Turbos:

Fabrication Does Get Complicated

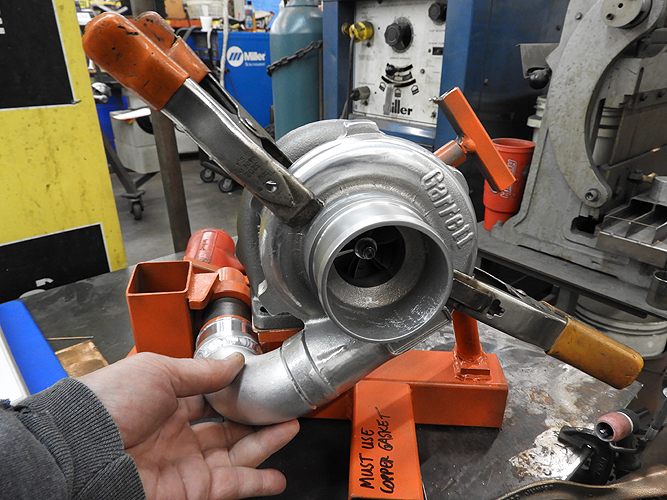

Fixtures and a lot of knowledge are required to make turbos

for EVOs Twin Cams, VRods, Race Bikes, and specialized ORCA

motors with Bosch Fly By Wire Motorsport Controllers etc...for

both Bonneville and Street bikes. These fixtures are just the

tip of the complexity involved. 45 years 1980 to 2025.

Pallets of raw parts, thousands of

dollars in waterjet and laser cut parts and mandrel bending,

plus over 1000 pages of documentation, software, CAD files,

many three ring binders, and hopefully not too much brain

fade.

Push the art because you want

to...not because anyone asks you to, or that anyone

understands, or even if they are prepared to ramp up to do

tuning or testing. Interesting business. Typical request "I'd

like about 300 bolt-on horsepower". People.

Example: Turbos

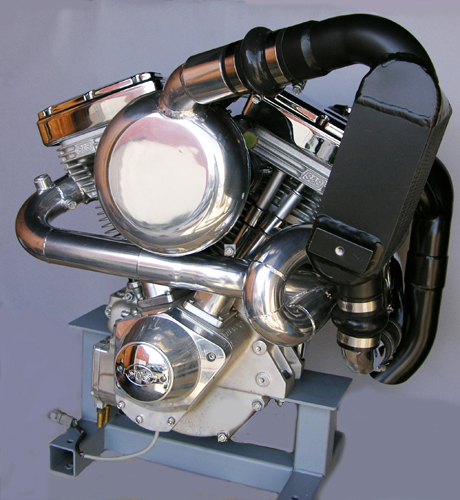

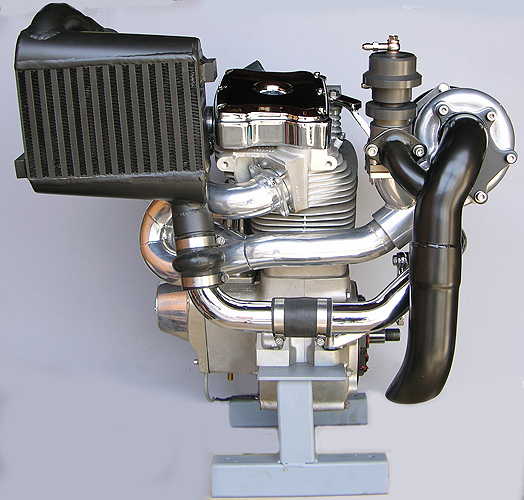

Done Correctly: ORCA EVO 113"

113" S&S Special Application EVO ORCA Motor with B1 heads.

300HP Intercooler (frame mounted). 360Hp Turbo (engine mounted).

Positive oil scavenge.

Merge Collector stainless 2-1 collector with

double slip joint.

Does not "hammer" the

turbine by placing exhaust turbine at front port.

Allows timed scavenging of

cylinders

Less EGR inlet dilution as

pulses are not "aimed" at the other exhaust port.

Less spikes in power

delivery

Turbo mounted independently from the turbo exhaust manifold.

Slip header to turbo pod.

Motorsport Computer Controlled:

(1)1000 psi water injection;

(2) Phase Anti-Phase Closed Loop Boost control;

(3) Dual Fast Acting Type-K Thermocouples;

(4) Dual Wideband NGK/NTK lab grade O2 sensors

(5) Fly

by Wire Bosch PPS/TPS.

(6) Mil-Spec Main Harness. 34 sub harnesses. 106

Connectors. 484 Wire Terminations

(7) Sequential Cam Triggered Fuel Injection

(8) Inconel 600 psi seal ringed cylinder head. Gasket-less base

cylinder sealing.

(9) Inconel valves. Dual Spark plug. . Forged and coated Turbo

pistons.

(10) Digital Programmable Dash

(11) Programmable Traction Control

Details:

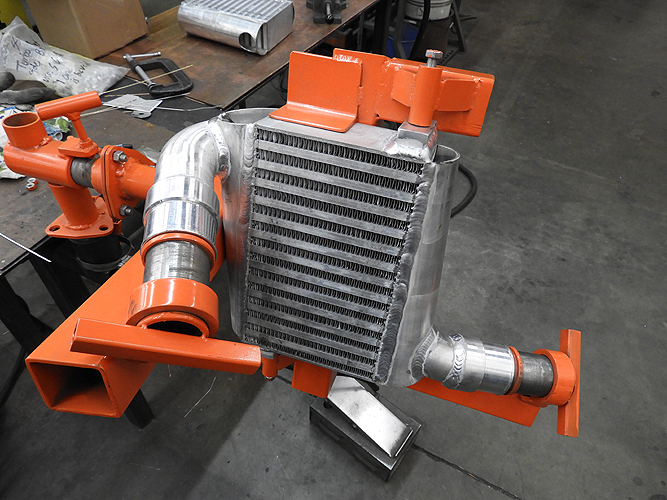

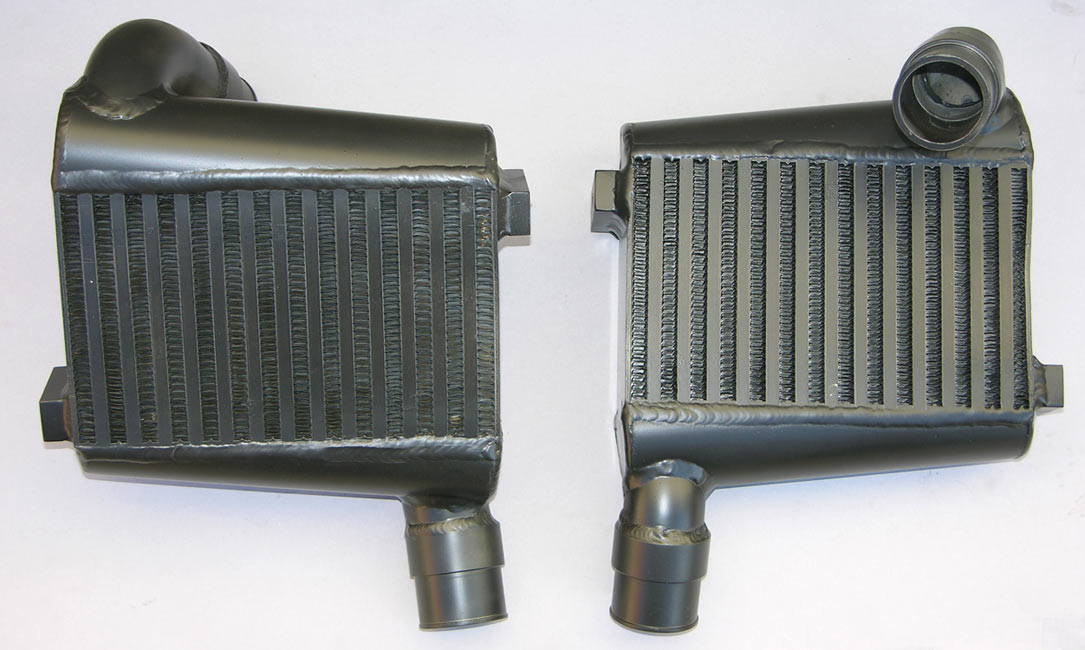

Intercooler Fabrication

Here we are welding up a 300+ HP HD Turbo Intercooler after

machining and prepping the parts for it. Air enters and exits

at the larger part of the tapered end caps. After this the

intercooler goes for ceramic coating. This chews up a couple

of days off and on. Expensive.

The intercoolers

are sized to drop the inlet charge temperature closer to

ambient i.e. if the charge temperature pre-intercooler is

150F and the outside air temperature is 80F and the bike is

moving at cruising speed and then under acceleration, at say

8 PSI, then the inlet temperature will be closer to the

ambient 80F.

Use our Intercooler

Calculator to see what your boost inlet temperatures

are.

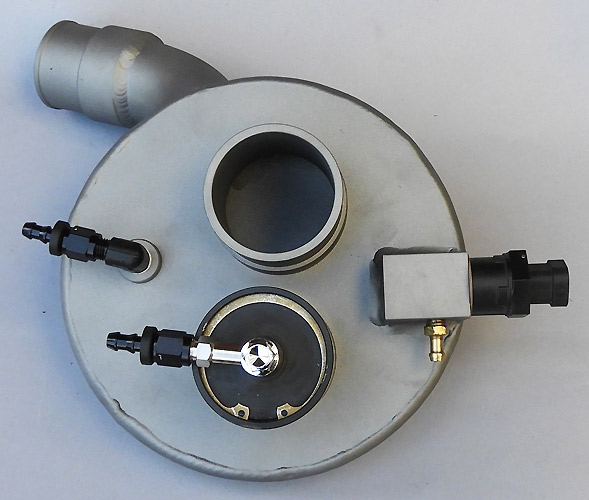

Various spigots for turbo connector

hoses..EVOs, Twin Cams, OEM EFI systems, Cosworth Pectel FBW

systems...For our intercoolers and plenum chambers. Does get

a bit complicated, but with specialization and the intended

uses, it always does.

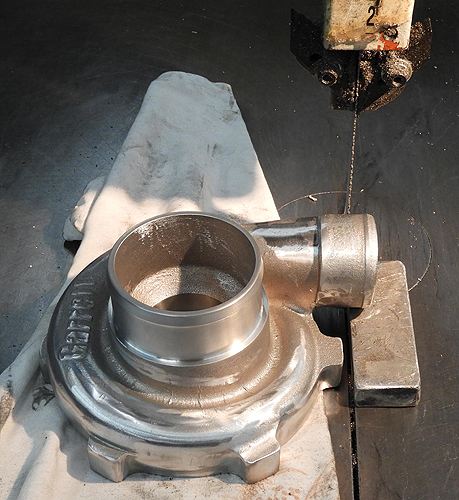

Twin Cam Ns EVO: Genuine Garrett Turbo.... Raw

Castings

Start out with a

genuine ceramic ball bearing Garrett Turbo...Add custom

housings and you are at $1,500.00 before we start

modifying things for a Harley V-Twin.

They just don't fit optimally the way the

come...so we have to do surgery.

We use genuine Garrett Ceramic Bearing 360 HP

Turbochargers. These come in as raw, machined castings in

iron and aluminum. We then modify the compressor, exhaust

housing and the turbo center section with machining.

welding, sanding, and bead blasting operations.

The parts are then ceramic coated internally and

externally for corrosion protection, heat retention, and

heat dispersion. With more that 25 years going to the

Bonneville salt flats, we know how important

anti-corrosion coatings are...not to mention operation in

the real world.

Then there are the 44 years of previous

fixtures dating back to Shovelheads and parts which have

since been discarded. Gets expensive. Thousands of

man-hours.

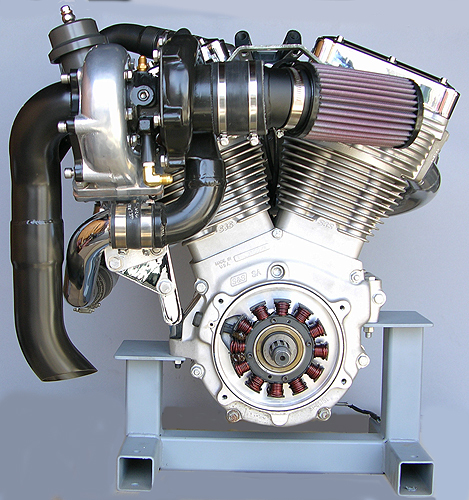

Many Hours Later..Orca Turbo Pod

On a Twin Cam 95" the turbo puts out about 165hp and 164

ft/lbs torque @ 9 PSI of Boost.

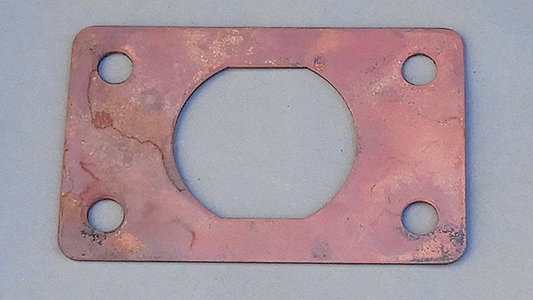

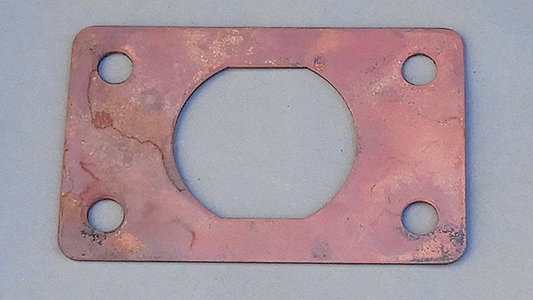

Annealed

Copper Turbo Gaskets

Cut with a water jet... Heat Cherry Red with torch then drop in

cold water. Turns copper into a soft condition. We anneal all

our turbo and wastegate gaskets. No goo or silicone.

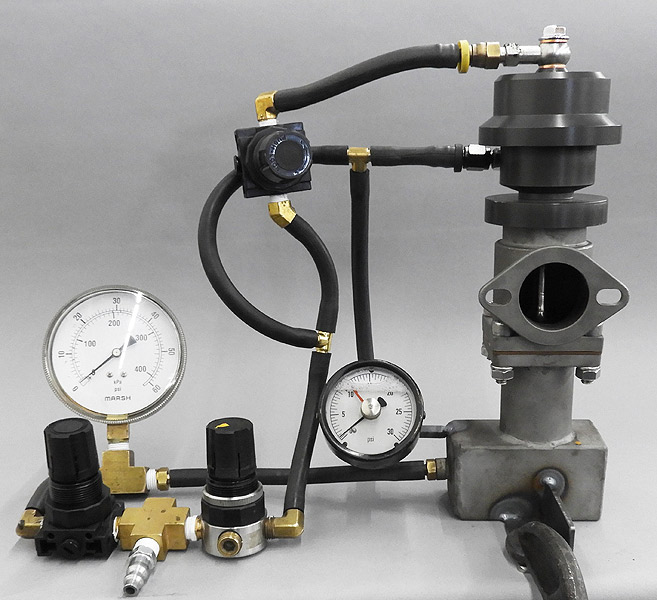

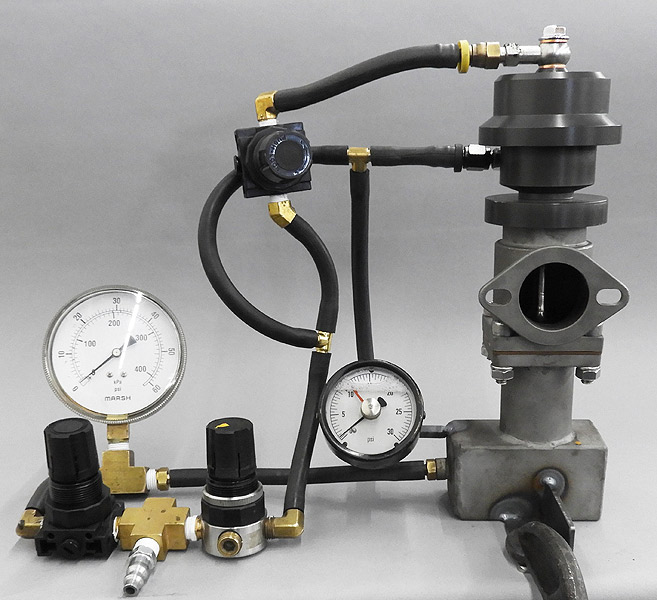

Wastegate

Testing

With three

regulators we test Boost Pressure, Exhaust Back Pressure,

Adjustable Boost 8-25 PSI, and wastegate valve sealing.

Here boost is controlled by a pneumatic controller. With

advanced Electronics we can control the wastegate with

Phase and Anti-Phase fast acting solenoids.

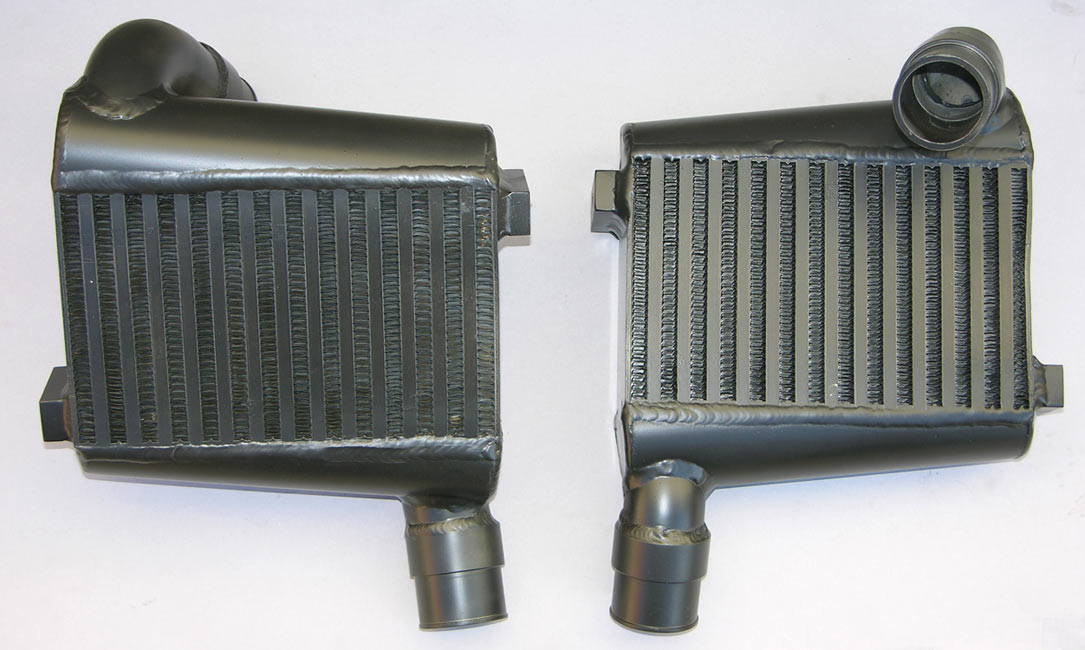

300Hp

Intercoolers

RB Racing Harley

Turbocharger System: Intercoolers Coated in Ceramic Black

High-Emissive Coating for optimal performance and corrosion

protection. You can run your big twin through the gears at low

boost and about 180 Hp and the intercooler discharge

temperatures will be close to ambient. We don't use small

restrictive intercoolers or, even more stupidly, put the

intercooler under the bike like one firm does.

Airflow in and out of the intercooler must be smooth so each

of the 13 channels flows the same which is why the hats must

be tapered. You cannot simply butt the turbo discharge up

against the base to the intercooler as some firms do.

Front view left above. Rear view right

above. The intercooler mounts securely with billet clamps to

the crash bar. The intercooler is rigidly mounted and the

turbocharger and turbo plenum move with the rubber mounted

engine. Special flex bellows couplers (see below) connect the

moving and stationary parts. Proven in years of use.

To protect our Harley Turbo Intercoolers against

corrosion and to dissipate heat we use special Ceramic Heat

Dispersant Coatings which are applied after we fabricate and

blast the parts. These coatings are impervious to carb

cleaners and other chemicals as well as normal soap and water

cleaning. This is not powder coating as that would be an

insulator and degrade the intercoolers efficiency. Plenum

chambers are also coated.

Twin Cam 88 Plenum Chamber. Optional water injection port.

These designs are over 25 years old...Sort of tells you how

far we were ahead even in the EVO days.