ZX-11 Turbo (Note: These

were discontinued over 25 years ago)

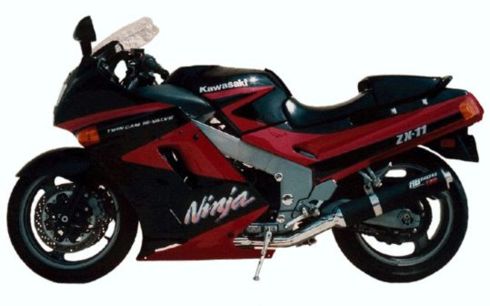

Fear no Hyabusa

500 HP! Not a 200 HP hodgepodge blow-thru carburetted piece of shit! There is no point turbocharging your ZX-11 if it can't make more hp than anything on the planet. RB Racing only builds sophisticated state of the art systems that feature: digital electronics, intercoolers, oil scavenge systems, air-by-pass and turbo blow-off valves, pneumatic billet diaphragm wastegates, dial-a-boost controls, ceramic coated custom designed turbos, stainless feed and scavenge lines; custom throttle bodies w/2 injectors per port; sophisticated idle air control system; closed-loop operation; IBM PC programmability; large volume plenums w/equal air distribution; digital Air/Fuel Ratio meters; sensors for air temp, engine temp, throttle position, manifold pressure, IAC, O2 Lambda, altitude compensation; and 600 HP fuel pumps.

Maxton on My Mind

Two ZX-11 Turbos protecting a 220 mph scooter headed for Maxton. Checker board floors always means the deal is serious. Probably not a good idea to try to peek at all the serious hardware hidden on the scooter. Rumor is that it has two turbos, a supercharger and is running on nitro. Well, if the scooter blows up or the government confiscates it, the two surly characters Bob Shammas and Jamie Barden can always race the low tech ZX-11 Turbo pit bikes. Cold air, asphalt and the clock. Cruising at 200 plus, chin on the tank, half a tank of race gas and no cops...Blues Brothers. Results: after passing tech and qualifying runs for license, 202 mph @ 10 psi with some minor coolant leaks. Next: Up the boost to 18 to 20 psi and increase the speeds. Watch the movie

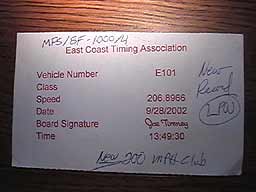

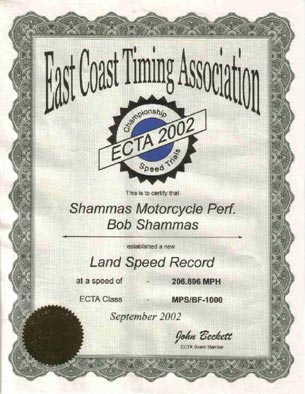

28 Sept 2002: Bob Shammas (R) raised the record for the 1000cc class with his RB ZX-11 Turbo to 207 mph...and he still had another gear to go. His pit scooter clocked 28 mph during a course inspection. Jamie Barden rode his RB ZX-11 Turbo to 209 mph. Wayne Pollack (L) rode his Hayabusa with Nitrous to a new record of 205.00 mph...Wayne is tripping on the Dark Side to stay in touch with the God of Speed as he's usually seen on record setting Harleys.

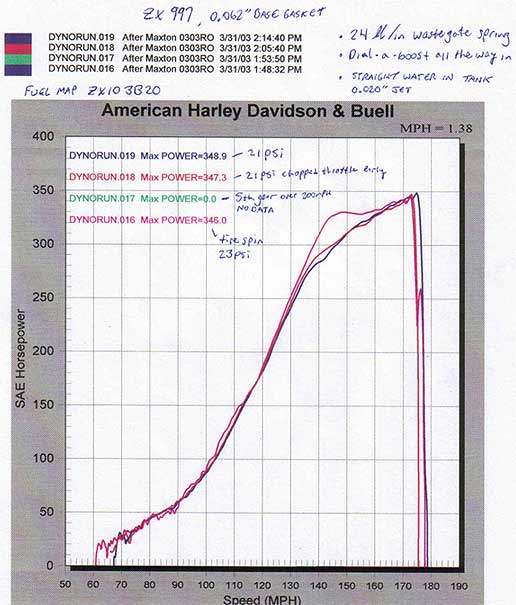

30 Mar 2003: Bob Shammas raised his record to 218 mph at Maxton. He also dynoed the bike, the results of which are posted above. Inertial dynos are not the way to tune RB Racing Turbos...Bob Shammas only used the dyno to verify his Autocal.V6 Professional software predictions.

Bob went on to set a 221 mph standing mile

record

with his ZX11. Bob Shammas retired from a long history of

drag racing

and speed contests, married again and settled into a new

house.

Unfortunately Bob had a severe brain injury riding a dirt

bike in which

another rider was killed.

Mike Chestnut

A customer we built GPZ750 Turbo parts for

(Mike Chestnut) said he was going to build his own turbo and

wanted us to order him a turbo. He choose the wrong one. We

order it

anyway. One year later he can’t get it done by conning his

“friend” to

do the work for free so he asks it to build it “his way”. We

do. He

then sees our ZX-11 design and wants it changed to "our

way". We did.

He also

took it upon himself to take down the license plate numbers

of three

out of state bikes we had in our shop. He threw a fit when

he saw we

were working on bikes like his but not his exclusively. He

tracked

these people down and told them RB Racing was tearing up

their bikes

doing wheelies and loaning them to customers (the bikes were

never

operated) for the sole purpose of spite. The people came in

unannounced

one Saturday and pulled their bikes and tried to sue us for

not

finishing their

bikes even though they had not paid. They also wanted

additional work

done for free and even told us they would take our fixtures

back to

Colorado and build our parts for us. They announced they

were going

to “own” our business. They got nothing, zero, zip, from us.

We were

out eight weeks

labor and fabrication.

After this we let the original customer, Mike

Chestnut,

ride his ZX-11 RB

Racing Intercooled EFI Turbo around the block and then

disabled it as

he was moving to Tennessee. He was amazed how “perfect” it

was. We told

him he could have the missing parts when he owned up to what

he had

done and pay for any losses we had. He was a coward and did

nothing. He sold the bike to Jamie Barden to avoid

dealing

with us, who paid us for the

missing parts, getting a $17,000.00 motorcycle for

$6,000.00.The bike

ran 210 mph on it’s first pass at Maxton. The seller, Mike

Chestnut,

was there to see “his bike”. It wasn't his anymore.

Last seen after collecting a large insurance settlement for being run over by a double dump truck/trailer in California, and moving out of state to have custom house built, Mike was chroming parts for pinball machines in Gallatin, TN...Does he have a chrome shop...no he doesn't. We were happy to hear later on that he lost his left leg in another motorcycle accident..and were glad it was his left shifter leg. Acting as a middleman for chroming is safer than motorcycles for him. He used to laugh about how he was charging people $400.00 to ground one wire in a GPZ750 turbo ecm. Cosmic pinball got him. Karma.

Mike was killed we he ran into a Turkey

Vulture on

some new Kawasaki. We hope the Turkey Vulture survived. He

should have

stayed off of motorcycles. Third strike and he was out.

Click on photo to enlarge

Sophistication and practicality

These kits are docile enough for daily commuting, short-hop usage, reliable enough for long trips and are controllable enough to be road raced. All EFI components are water, corrosion and vibration proof with many miles of testing and 10 years of development. All systems are capable of achieving 500 HP. We recommend a maximum of 12 psi on Pump Gas (92 octane). For 12-30 psi we recommend race gas and water injection. All RB/RSR fuel injections are compatible with stock and after market ignition systems. Contact RB Racing for specific recommendations relating to lockup clutches, connecting rods, pistons, water injection, compression ratios and ignition requirements.

All components fit under the fairing. There are a few minor mods but cornering clearance is unaffected. There is a lot more to turbocharging than being a plumber and routing some tubes and hanging a turbo on your bike. There are thermal and air flow engineering considerations. Most often, poorly designed systems simply try to overcome their design limitations by running more boost then blowing up. RB Racing gives you the benefit of 25 years of design experience so you can make the maximum reliable power from a balanced well engineered system. Six of our customers have gone into the prestigious 200 MPH Bonneville/El Mirage 200 MPH Clubs with 100 percent reliability, with over 1000 miles of actual competition at 190-220 mph, running 18-24 psi with zero engine problems (Harley, BMW, Kawasaki,Suzuki, Honda, Triumph).

Vertical integration means no compromise

We have been doing fuel injected, intercooled turbos since 1985 and ALL RB Racing turbo systems have been fuel injected since 1989. People have attempted to duplicate our earlier draw-thru and blow-thru carbureted designs but they have not set one record. RB Racing remains the only turbocharger specialist that manufactures its own closed-loop IBM PC programmable EFI system designed especially for motorcycles, and the only manufacturer that produces its own custom throttle bodies for each application. There can be no compromise. All components are designed in-house to be the best possible. There is no compromise that comes with trying to adapt components not designed for the specific job at hand.

Click on photos to enlarge

Dual computer fuel control system

Fuel Injectors/Fuel Control: Your RB Racing ZX-11 turbo kit is shipped with a dual strategy fuel control system using two computers. The RSR 800i ECU is connected to an 8 injector wiring harness. Four of these injector leads are connected to your primary (upper fuel rail) injectors which are 17 lb./hr which is sufficient to control your idling and full power requirements to 0" Hg. Four of the injector harness leads remain unconnected. The (4) 17 lb./hr injectors are programmed from 15" Hg to 0" Hg with your RSR ECU using a 1 Bar Map Sensor. This gives you extreme control of your normal driving in a programmable 16 x 16 matrix in your RSR ECU Autocal software.

A secondary fuel computer, an RSR AIC 400 controls the four secondary (lower fuel rail) injectors which are 42 lb.hr which covers the engine's fuel requirements from transition into boost to 30 psi. The RSR AIC 400 has four selectable maps (lean to rich) and a plus or minus 10% trim knob. The four maps and the trim knob can be changed manually without the use of a PC. The RSR AIC 400 has its own four injector wiring harness and 3 Bar MAP sensor.

If you wish to initially or, at a later date, you can use the RSR 800i ECU to control all 8 injectors and remove the AIC 400. If you elect to run 8 injectors configured as primary/secondary under control of the RSR 800i ECU the injectors MUST be the same size. For 475 Hp at a BSFC of .45 lb./hp/hr you would use eight 34 lb./hr injectors.

Mechanical considerations

Mechanical

Considerations: Modern (1987 up) 4 valve/5 valve combustion

chambers

are generally not prone to detonation for brief excursions to 12

psi.

Do not confuse boost psi with airflow in CFM. Turbo nozzle

discharge @

12 psi from a small turbo IS NOT the same as 12 psi from a

larger

turbo. RB Racing supplies only large CFM turbos that will

produce more

power at a given level of boost than will less efficient turbos

without

custom designed compressors. Your modern 16/20 valve engine is

designed

to breathe in the narrow window of 10,000+ rpm and, as such the

effective compression ratio is less than the stated 11.0 to

12.0:1

manufacturer's static compression ratio. When you factor in

camshaft

duration necessary to allow sufficient inlet/exhaust overlap @

10,000+

rpm your effective compression is much less.

On (1987 up) motors we

normally recommend you leave the stock compression/pistons in

place. If

you are hell-bent on "building" your turbo motor do not lower

your

static compression ratio below 10.0:1. For camshafts you can

increase

the valve lift but do not shorten the duration and therefore the

overlap of the camshafts. Overlap on a turbo motor prevents

overworking

the exhaust valve by allowing cooling of the valve to take place

which

also helps to prevent the onset of detonation. In general the

lower the

compression ratio the more boost you can run and the more power

you can

make. If you build a 50 psi. 6.5:1 C.R> motor it will produce

a lot

of power but be a "dog" everywhere below this. Early (1979-1986)

2

valve motors and motors with less efficient 4 valve chambers

probably

need 8.0:1 compression ratios to survive.

For your Kawasaki we recommend you retain your stock connecting rods and pistons as they seem well suited for 300+ hp. If you are hell bent on 500 hp then forged pistons and Carrillo rods are a good choice. To achieve 500 hp on a Dyno you are going to best be served by augmenting your motor with Nitrous Oxide for two reasons: (1) The intercooler will be ineffective on a static dyno as no fan will simulate 200 mph airflow. (2) The NO2 will cool the inlet charge and provide a brief power boost. Normally we don't recommend the NO2 due to it's vagaries related to temperature/pressure etc. , but in the case of Dyno Heroes it's a necessary evil. Hit the "Squeeze" at your own peril!

Lock Up Clutch: Without this your clutch will slip pass 200 hp...Mandatory on high output turbo bikes.

Ignition: Leave stock item in place. Since you are hell bent on fooling with timing we will ask you one question..."What is your pressure/crank angle" at your new, guessed-at settings. Ignition is a difficult thing to evaluate. Bad designs use retarded ignition timing to prevent detonation . Retarded ignition brings its own can of thermal problems. Proceed at your own risk.

Click on the title above to go to our RSR Boost Compression Ratio Calculator. This allows you to run scenarios of how boost affects your effective compression ratio as modified by altitude considerations. It will give you a good idea as to why turbos go so fast and also how to plan your motor for your particular circumstances. Knowledge is power.

ZX-11 Kits include the following:

(Note: These were discontinued over 25 years ago)

Your ZX-11 comes complete with the following items.

RSR800i (8 injector) Closed Loop Fuel Injection ECU. IBM PC Programmable

Custom Wiring Harness.Sensors: T.P.S., Air Temp, Coolant Temp, M.A.P., O2, I.A.C.,Altimeter

Fuel Pump/Pressure Regulator/Fuel Filter/Dry-break Fuel Return Port

8 Fuel Injectors w/Anodized Fuel Rails

Two Computers:

(1) 1 Bar--RSR800i ECU, PC Programmable

(1) 3 Bar--4 Map Select AIC 400 w/plus or minus 10% trim adjustable on the "fly"

User Software and Serial PC Cable

42mm Throttle Bodies (4)

800 CFM (500 HP) turbo

Positive Oil Scavenge. All Oil Lines/Fuel Lines and Fittings

Air to Air Intercooler

Large Volume Plenum Chamber w/45mm Compressor By-Pass/Blow-Off Valve

Boost Master Wastegate w/Dial-A-Boost (8 to 35 psi)

4-1 Header--Ceramic Coated

Exhaust Pipe w/Integral Race Pipe

Lighted Glycerin Filled 0-35 psi Boost Gauge

Specific Requirements: You must send to RB Racing the oil pan and three oil lines for modification: See attached sheet.

Costs: $7500.00

Installation Time: About 10 working days to dismantle, install, check, and initial run-in.

Options to the Basic Kit

Options: Autocal Professional Software $350.00

Air/Fuel Ratio Meter $225.00

Eight 34 lb./hr Injectors @ 55 psi $693.20

Tattle Tale for Boost Gauge (holds highest pressure) $75.00

Ceramic Bearing Turbo (More Hp, Faster Spool-up) $500.00

Water Injection:Simple: License Plated Mounted. Hard Anodized. Turbo Pressure>5 psi. Meters water to turbo inlet $295.00

Electronic (9th Injector): Large Hard Anodized reservoir.Pump, Regulator, Electronic Injector. Requires constant maintenance to prevent corrosion problems. Meters water/alcohol directly into inlet plenum. Suitable for periodic Speed Contests not for daily use. $750.00

Liquid/Air Intercooler (Includes Pump/radiator/pressure cap) $950.00

Lock-Up-Clutch (Does not include Clutch Cover Extension $349.00

EGT Gauge & Port $395.00

Training: With the purchase of an RB Turbo Autocal Software training sessions are offered

1/2 Day $250.00

1 Day $500.00

Terms and Conditions

Terms & Conditions: Contact RB Racing for availability and current terms for payment. Turbo systems are not on the shelf items, are very complex and are treated as custom orders. Custom orders are sold on an "as is" nonrefundable, nonreturnable basis. If for any reason you cancel your order prior to delivery or refuse delivery you are liable for the full amount including the shipping charges. It is not RB Racings responsibility to sell or dispose of custom orders which have been cancelled or refused.

Warranty: None. All parts are thoroughly checked prior to shipment. Due to the varying skills of the installers and the potential for abuse no warranties or guarantees are offered. If you have any questions call RB Racing before you beat the parts into submission with a large hammer...and never put your turbo or oil lines near a shop grinder or you will destroy your turbo instantly.

Returns:

We won't accept them. These are one way custom items. You cancel

or

can't pay after we've spent 8 weeks...There are no refunds.

Technical after sale support

Technical Support. We do not have an open ended technical support policy to account for your inability to follow instructions, configure your computer or think logically. The parts are logical in their assembly. Detailed start up instructions are provided. Tuning and software tutorials are included in the Professional Software package. Approximately 40 pages of documentation and instruction come with the kit. We accept a limited number of tech support calls not to exceed a total of one hour. Beyond this we offer support on a prepaid retainer or credit card basis. Call RB Racing for details.