RSR Fuel Injection - Harley

Note: As of June 2018 these are no

longer being shipped or manufactured by RB Racing. We did it for

26+ years when there was no efi. We are transitioning to higher

end Motorsport Electronics in support of our Turbocharged EVO

Engines.

Lots of records were set with these. Very few

people actually know much about efi... In 26+ years we

only dealt with a few people who used our software and hardware

that did any tuning at all...Most simply took what we set up for

them to set records...Harleys, Suzukis, Kawasakis, Yamahas,

Truimphs, BMWs, Hondas. Everyone wants answers, does not want to

learn and expects free help.

These days most serious racing involves high end

electronics, traction control, closed loop boost control, data

logging and wiring harnesses that cost more than the

electronics. This involves tens of thousands of dollars in

hardware and support issues.

We did it for pennies on the dollar and gave free

support and tuning. OK to set records. Not a good business plan

however. Time to move on.

What is written below is for historical

purposes...

RSR Closed-Loop Electronic Fuel Injection for Harley Davidson Big Twins and Evo Sportsters!

Touring Bike?

113 ORCA in a rigid frame. Owner assembled bike, loaded it in a truck, drove from East Coast to RB Racing in California. We spent two days trouble shooting the new bike that had never run, programmed it with Autocal.V6. The owner then dropped off the rental truck and drove the rigid across country back to the East Coast averaging 50 mpg. Not exactly what we would recommend, but in this case it worked out. To knock some noise off the RSR 2-1 Pro Stock we welded on a Pro Stock Spyder muffler.

We didn't even put the bike on our dyno...Just wrote the program and rode the bike a few times. Closed loop, high compression, 113" ORCA with S&S SA B1 heads.

145" Closed Loop RSR EFI

If you have a 145" Tribute Engine we have closed loop efi systems that are throughly proven for over 16 years and hold Bonneville, El Mirage, Maxton and AHDRA records. Simply send us your Super D inlet manifold that is matched to your inlet ports and we'll return you a closed loop efi system. Pictured above to the right are our new ecus...the older units to the left were upgraded to a new billet enclosure. With our Autocal.V6 Professional software you can write a calibration for any motor in minutes without the need for "dyno experts".

Reliability

If you absolutely, positively have to have the best fuel delivery system in the world, this is it! It will outflow, outperform and just plain out maneuver any carburetor or EFI system...and do it with 100% reliability, rain, snow, gunk bath or whatever you can throw at it! Even the Evil Vibration God that rules the Harley Underworld can't kill it.

RB Racing has over 15 years of experience building, tuning, developing, and racing Fuel-Injected Harley Davidsons...both normally aspirated and turbocharged. We actually manufacture our own fuel injection systems...from bare ecu boards to throttle bodies to fuel rails and wiring harnesses and build these parts to an insane level of quality and reliability.

Waterproof

We never have had an ecu or wiring failure because early on we realized that heat, vibration, water, wind, Gunk, pressure washers, crappy electrical systems, abraision, and various sharp objects and expert mechanics with creative stategies were all going to conspire to kill the fuel injection. Our wiring harnesses and connectors are waterproof. Hard Anodized billet, cnc machined, ecu. Potted electronics (upgradeable). Gold-plated, waterproof connectors insure long term reliability.

We have seen grit from bead blasting and sand blasting in gas tanks and bondo dust from frame work that clogged filters and injectors; shitty crimp-on connectors from second-rate ignition systems that fail; dead regulators / rectifiers, defective alternators, shorts in the oem wiring harnesses, crappy Harley switches and defective starter solenoids and starters as well as the usual shit that falls off or breaks like shift levers, license plates, collapsed pushrods, defective lifters, cracked engine cases, galled camshafts etc. etc....all things out of our control...and all things that somehow get overlooked when things go wrong and the finger gets pointed at the fuel injection when things go South.

The RSR EFi does not fail.

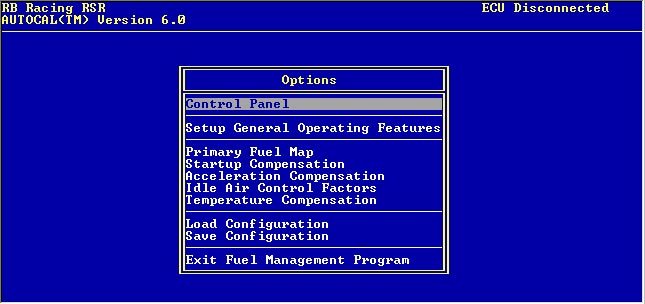

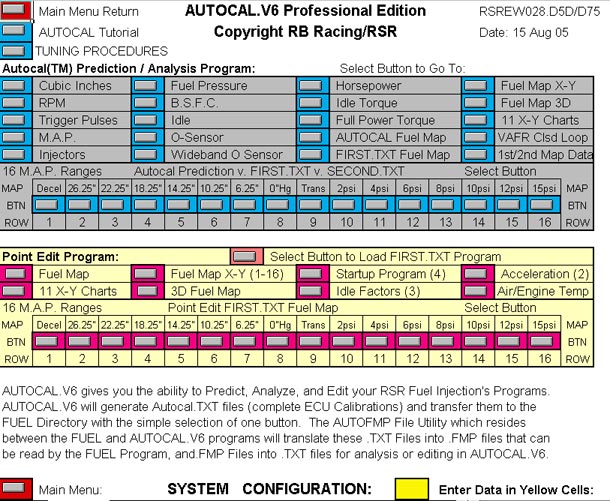

IBM Thinkpads...Autocal.V6

We supply you with a used IBM Thinkpad Laptop preloaded with all our software for both serial Fuel communications and Autocal.V6 prediction and analysis. The units are tested on the RSR ecus we send out so you can get going right away. We have decided not to spend hours on the phone diagnosing computer or software installation issues. For $650.00 you get a fully functional laptop with over $750.00 worth of software already installed. All instructions including your personal ecu files are preloaded and tested on a flow bench.

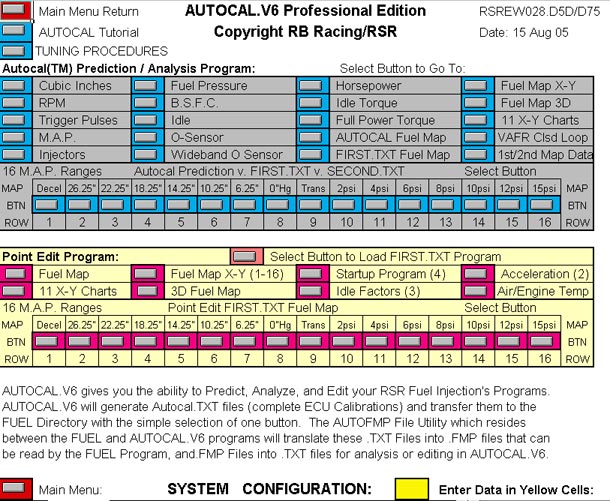

With Autocal.V6 you can write a program for any engine in a few minutes. With our Fuel serial communications software you can edit your RSR ecu and maintain all of your ecu calibration files.

The Thinkpads come with either 12" or 13.3" lcd screens. All software is preloaded and tested. The laptops come with AC power supplies and our special serial communications cable that attaches to your RSR ECU wiring harness.

Peripherals

For things like fuel pumps, we have sorted through various suppliers looking for the best pumps for our applications. Some were smaller than others, which was a plus, but the quality varied and formed metal nipples or plastic casings could crack...and some had shitty push-on blade connectors that, while they worked, were questionable. Water proofing these tended to be a hassle.

Pumps have to be of very high quality and are typically rated for about 3,500 to 5,000 hours life...assuming you donít try to pump even microscopic grit through them...and if you donít run them dry. We sorted though many manufacturers and tend to use pumps that have a German accent...pumps which have weather seals on the connectors, screw-on terminals, banjo fittings, and a distinct lack molded plastic parts. We make sure you filter the gas before it gets to these expensive items.

Powder coated mounts, rubber isolated and stainless steel hardware. Different pumps for different horsepower ratings. The German pumps we use are static @ 400hp and 550hp....We like to see at least 30% bypass fuel at peak numbers so we use these pumps for applications up to 307.7 hp and 423hp respectively.

For larger applications, like Big Inch Pro Gas Turbos, we use larger pumps and regulators from SX Peformance.

These allow the use of 600+ hp capable turbochargers and remove restrictions that would occur in regulators with less bypass area. It all gets expensive.

New RSR ECU's for 2008

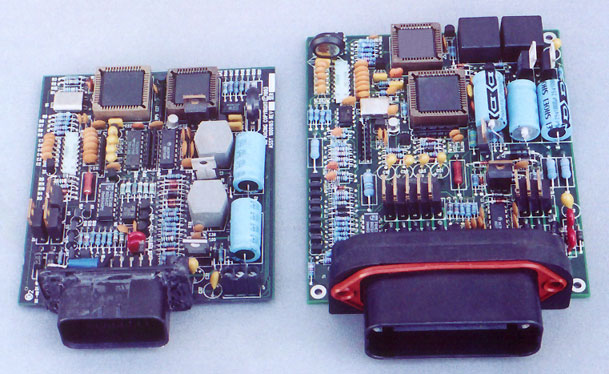

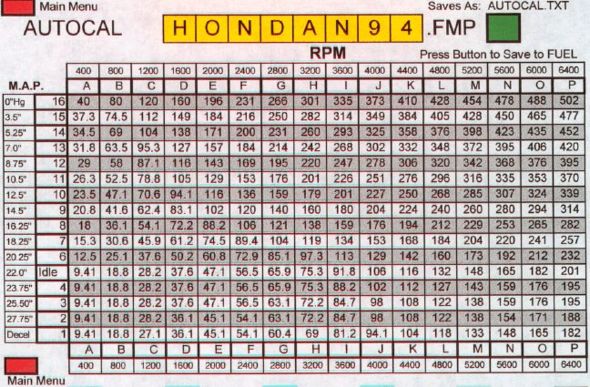

On the left our earlier RSR ECU which was the first fuel injected unit to set both Bonnevile records as well as National Drag Racing championships. The newer unit on the right continues with the same reliability but adds a few features that we will be using in 2008 to set more records.

Our electronics are conservative but use only the highest quality components rated for the the most demanding automotive specifications which are tougher than mil-spec standards. Automotive parts must be made in the millions, exist under a closed hood in a hostile environment and make it past the warranty claims and the blood sucking lawyers. We only use the highest level of automotive connectors which are all waterproof and rated as being pretty much impervious to heat, ozone, chemicals and born-again mechanics. Mechanics seem to have an insane desire to pull on wires as hard as they can...itís easier than gently moving things for easier access.

The first generation ecu (to the left above) would support up to eight high impedance injectors with either all eight firing or four primary and four secondary firing in a staged manner. The system would support two low impedance (2-3 Ohm) injectors. This first generation ecu had a 23 pin AMP connector and a 3 pin serial communications connector for a total of 26 input/output wires.

99 Resistors, 52 Capacitors, 26 Transistors, 28 Diodes, 15 Integrated Circuits. Etc.

Our new ecu (to the right above) is an expansion of our earlier design and can support up to eight low impedance injectors or up to 32 high impedance injectors and has the capability to run two map sensors for some interesting possibilities. We also included three input trigger circuits to cover distributor, coil, magnetic and hall effect inputs. The serial communication wires are now incorporated into the wiring harness. The new ecu uses a hyper-expensive Deutsch gold-plated waterproof 40 pin connector that is specifically designed for harsh environments like earth moving equipment that spends decades out in the roughest conditions. We use the same connectors they use on million dollar heavy industrial equipment.

Bulletproof Reliability

To insure complete reliability we design four layer circuit boards with multiple ground and power planes and only use the highest tolerance components. It's getting tougher to do ultra-reliable through hole designs where we can thoroughly control all components in house...the future is all surface mount and hybrid components. These parts are, as they say, bullet proof. For the next period we do not have to deal with debonding or heat expansion issues that are prevalent in surface mount components.

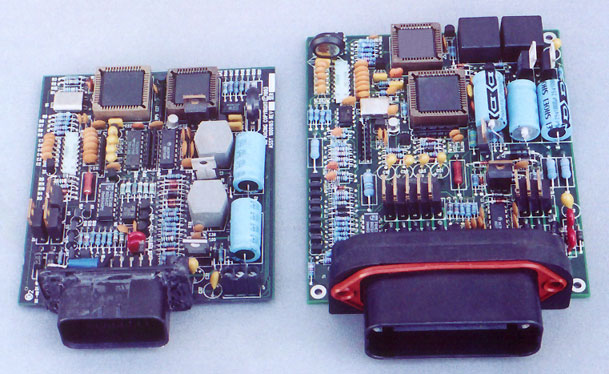

In the first generation of RSR ecus (to the left above) we knew we had to suspend the circuit board independently from the mounting system so we designed a four part ecu enclosure...a two piece slide together hard anodized aluminum extrusion with machined end caps with recessed stainless steel Allen bolts that carried the load. The 23 pin waterproof connector was firmly connected to one of these caps and the circuit board was completely free of any strain and was fully encapsulated to protect all its components from environmental damage as well as from vibration.

The first generation ecus worked well for 15 years (1989 to 2004). The end caps required machining on all six sides and were a bit of a hassle to assemble. The 23 input/output wires were supplemented by a three pin pigtail assembly that provided serial communications, for a total of 26 wires going to the ecu.

When we sold out the last of our RSR Fuel Injections we decided to re-evaluate the older design and take a fresh look at things. We decided to build a two piece clamshell billet enclosure with overlapping seams and thicker walls. The overlapping seams provide an added measure of protection against electrical interference as long seams act like an antenna. By going to a two piece bolt together structure we eliminated a lot of small fasteners and the two separate end caps of the earlier design and made a tougher part. The clamshell is held together by four stainless steel Allen cap screws with captured, recessed nuts.

Not a Stock Replacement Deal; Not an Add-On Deal

There are too many compromises integrating with the oem fuel injection systems whether they are Weber-Marelli or Delphi. The throttle bodies don't flow enough air, the fuel injectors are too small, you can't run four injectors if you need to, the fuel rails are not high performance items, they aren't set up to measure the right parameters, the fuel pumps are too small etc etc. The RSR 200i and 400i systems do not compromise airflow or performance. They are true closed loop systems that have more than a decade of competition and hold more records and championships than any other system. If you don't take a systems approach and realize that that airflow is "king" then you shouldn't take a half-way approach to performance. RB Racing has the integrated EFI / Exhaust System / Turbocharger solution to high performance.

Other People's Poor Engineering

One thing we get a lot of calls on is people wanting us to solve their fuel delivery problems on their supercharger and turbocharger installations, none of which came from RB Racing. Some of these manufacturers even get tired of customer complaints and tell the customer to call us. We do not offer bolt-on solutions to these situations. We can sell you a fuel injection system and Autocal.V6 Professional Software but the engineering is up to you. Unless you can do machining, welding, competent design work, and tuning, don't bother. Having to redesign and re-engineer other's work is a huge pain in the ass. You will be certain, no matter what we tell you, that RB Racing is going to straighten out the situation for you. We don't do remote control engineering. The fabrication and engineering is up to you.

No "maps" to download...Write your own for any engine

With Autocal.V6 Professional Software you can write a fuel map for any Harley...74", 80", 88", 113", 120", 124",131", 135" etc. etc. in minutes! High compression, turbocharged, supercharged...Gasoline or alcohol...Single or staged injectors...2 injector systems, 4 injector systems...1/2 Bar, 3/4 Bar, 1 Bar, 2 Bar or 3 Bar pressure ratios. No voodoo tuning where you keep throwing "maps" at the problem, hoping something will stick to the icebox. Of course, if you don't want to think, then there is no hope for you anyway. We write the programs for you but we don't come in the box with the product.

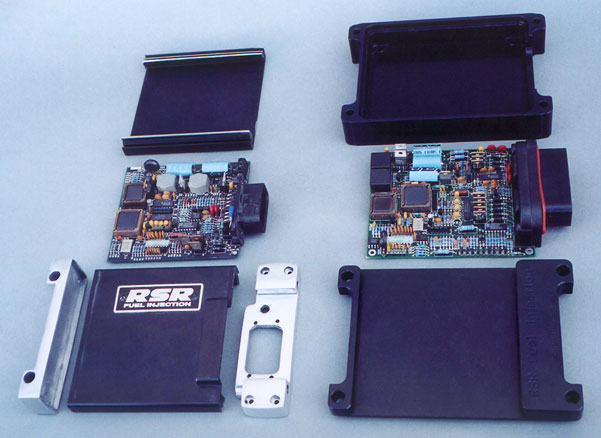

Whats a "Honda" fuel map doing on a Harley page. Well, we put our efi system on an old Honda Civic Station Wagon that we used to chase parts in and drove it for 50,000 miles. We wrote the map in about 5 minutes and never changed it. A rip-roaring 90hp 32mpg parts chaser. Honda went to the junkyard after a wreck and the ecu went on a Harley Fatboy.

Take a pdf tour showing 10 screen shots of Autocal.V6 Professional Software.

Resolution

Your RSR EFi system has a complex interpolation scheme that seamlessly gererates up to 3200 intersects or injector outputs.

Unlike notchy throttle angle systems your RSR EFi constantly monitors load and rpm and adjusts for temperatures, altitude, O2 feedback, acceleration enrichments and throttle postion to provide smooth transitions. If you think about it you will realize you really do not move your throttle very much, so throttle angle systems do not make much sense.

Serial Communications

Take a PDF tour of how you communicate with, edit, and otherwise manipulate your RSR Closed Loop ECU.

Throttle Angle and Speed Density

Almost anyone involved in selling efi for Harleys tells you you must use throttle angle and rpm to program your bike. This is a load of crap. If you actually ride motorcycles instead of trying to figure out stuff to sell people who actually do ride, then you know you really don't move the throttle very much. Most of the time we never use even 1/4 of the throttle movement.

Throttle angle systems are notoriously difficult to tune because airflow is inferred but not measured. The resolution in throttle position switches is just not that great and setting them with a digital voltmeter is required which is a huge pain in the butt. You end up with a notchy, poorly running scooter than makes you yearn for the simplicity of an analog carburetor.

Anything "written" for some application is going to be hypersensitive to t.p.s. settings as the trip points in the fuel maps will be different if settings are not exactly the same. This is not the case with manifold pressure speed density designs.

RB Racing uses manifold pressure and engine rpm as the major inputs, which is what we term a "speed density" system. Manifold pressure changes with load whether you are hitting a headwind or a hill even if you don't move the throttle, so you automatically have better fuel control. No automobiles use throttle angle. Think about it. Think about it again. Your car or truck runs fine. The next time you ride pay attention to how much you actually move the throttle. There is a direct correlation between density and fuel needs at any rpm.

Closed Loop O2

Your car is closed loop. Your truck is closed loop. We have been doing this since 1989 and we know the facts. Our ecu constantly self adjusts, chasing the elusive clean burn. Customers do the stupidest things and the bike runs"great". Sometimes we ask them to send us their fuel maps for analysis and we see entries that are way way off from their "editing"...but they are happy. The reason is we give the ecu the authority to change and chase things automatically. If we didn't, then the wrong entries could go out of bounds.

This is not a simple area from a technical standpoint via the 45 degree siamesed rod V-Twin. We have done the research and have the technical and mechanical issues ironed out. There are a lot of falsehoods about this in the area of tuning. Simply use our Autocal.V6 Professional software and you'll be running right away without ever making a decision about a specific millisecond value.

People ask us all the time about O2 sensor placement. We have for 15 years used the front cylinder because it runs cooler than the rear cylinder which is somewhat shrouded. The rear cylinder runs hotter and needs less fuel. With collector systems like our LSR 2-1 designs and the big twins firing order, each pipe "sees" the pulses from the other primary tube. By using the front cylinder and a 2-1 design in a closed loop system we keep things simple and provide the correct amount of fuel for both cylinders with a slight averaged bias to protect the rear cylinder. With our system you can operate in closed loop, even at idle, with long duration camshafts. Spark plug readings are equal.

Front and Rear Mythology

Hey! nothing is new...your engine is a siamesed crank 45 degree V-Twin and it's been that way forever. There is no mystery as to when the valves open or how much fuel the engine needs for either economy or power. It's just an inefficient air pump, piston speed limited, with minimal valve area and four sloppy pushrods.

The mystery has always been how to get the fuel into the motor with a carburetor with an engine design that shakes and has no runner length and had no appreciable inlet volume to dampen things out. Heat soaking, insulator blocks, wizards grinding inlet manifolds, single runners, dual runners, fins, atomizer screens, turbo gizmo vanes, compliance fittings, solid mount manifolds, XR750 reversed heads, Linkerts, Bendixes, SU CVs, Flatslides, Roundslides, S&S Super D's, E's, G's and Dual Throats, Webers, Del L'Ortos, Keihin CVs and a cast of others.

In the early 80's we were swamped with carburetor development and even marketed or own "PowerMaster" 38mm flatslide carburetors into the Harley Market. We went so far as to design an electronic enrichment circuit that was controlled by cylinder head temperature. We got to deal with Mikuni of Japan on that one...a long story of Dynos and deceit. They can always raise the prices and squeeze you out.

In the mid 90's we did a lot of work on a 41mm Keihin carb for Keihin of Japan. 56 mpg and outperformed Mikuni flatslides. We tested on all sorts of Harleys including Shovels. Never really made it to market. Keihin (Honda) ans their distributor Sudco dragged their feet due to contractual arrangements and cost considerations. Coulda-Woulda-Shoulda.

Everything sort of worked because those big flywheels had a lot of inertial and the pistons would suck the chrome off a bumper hitch.

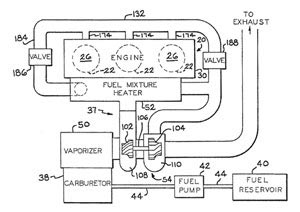

It's all a Heat Equation

Now with RSR EFI we use direct port injection and do no such trickery as phasing the injectors, looking at windows of manifold pressure versus crank angle because there is simply too much going on and we look at the whole thermal picture. Part of the game is puling heat out of the inlet and maintaining a homogenous mixture with high vaporization. Some of you might remember Smokey Yunick's work in this area.

We did extensive testing and with all the wild cams and compression variations etc we came up with what we consider to be optimum injector placement and an injector firing scheme that gives you equal readings on the spark plugs. We do not aim the injectors directly at the inlet valves...that would be a mistake. Combined with our closed loop system you can idle at stoiciometry even with long duration camshafts and for you techno-turbo wizards we pull the most heat out of the inlet tract with our firing scheme.

Self-Tuning Myth

People have the idea that closed-loop systems are completely self-tuning. This is a crock of shit. The truth is that every engine is different and, in the Harley world, difference is the norm as there are limitless engine build combinations.

In Detroit, Japan, or Germany, they spend thousands of manhours developing base maps for their automotive applications. On top of these base maps goes the closed-loop feedback mechanism controlled by mathematical equations or algorithms that govern exactly how the closed loop operation will function. These base maps are not written so the vehicle will run perfectly without feedback i.e. maps are not designed for open-loop operation. The strategy for closed-loop operation is different as fuel requirements under different climatic and altitude differences can be as much as 30%. Unless the base map is constructed for the particular application, the O2 feedback mechanism will not work properly.

OEM correction schemes allow only very slight learning corrections or they will "throw" an error code. They do this for a very specific reason i.e. if things are going wrong, which is indicated by the system trying to correct out of bounds problems, then a sensor or something else is wrong. They are not designed to make large swings to correct calibrations that are way out of bounds.

With our Autocal.V6 software you can write a specific base map for any application which will put things correct for your application without resorting to expensive dyno time. Our closed loop system then has a wide authority to self correct things. The key is that the base map is properly constructed for closed-loop operation.

To give you an example: You have the bike running perfectly with a specific exhaust. You change the cam or change the exhaust. Lets say you "overdid" things, being the greedy, power hungry fool that you are. The mid-range torque suffered at a gain in peak power. You have to flatten the torque curve in our Autocal.V6 Professional Software. The base map has to be correct, O-Sensor or not.

Then there are the electrical issues....we addressed these 13 years ago and others haven't figured those out yet.

O2 Sensor Issues

RSR Fuel Injection system use a four wire ultra high temperature Bosch narrow band sensor that we mount literally in the front exhaust port. Why do we use these and why is it put where it is?

1. Narrow Band O-Sensors are designed to do one thing very accurately....Run your application at exactly 14.7:1 air fuel ratio. This is known as stoichiometry and is the point where the most accurate combustion takes place. We don't want to have your motor, for the most part, running anywhere else.

2. Exhaust Gas Temperatures will be all the way from <1000 DegF to >1600 Deg F with maximum power occuring in the 1450 to 1600 Deg F range. These elevated temperatures will kill a Wide Band Sensor. We maintain a high (accurate) internal temperature with our heated 4 wire Bosch sensor. The Fourth wire is an additional ground reference wire that makes sure the sensor is grounded. All O2 sensors are very temperature dependent. By mounting the sensor virtually in the front exhaust port we maintain accurate readings.

3. Atmospheric O2 Contamination is a real issue that we have solved. Our narrow band Bosch ultra high temperature sensor is as far away from the outside world as possible. You cannot mount a wideband sensor in the exhaust port as it can be damaged from the heat. We have seen people put wideband sensors downstream in the collector where it is cool enough for the sensors survival but, as any performance exhaust is "low restriction", atmospheric pressure rushes back up the exhaust causing the sensor to read incorrectly. They have nothing but trouble and would be better off just reading the spark plugs.

The most reputable manufacturers of these units do not recommend their use on motorcycles, especially Harleys.

4. Maximum torque and Maximum power are not issues related to O2 control in any manner whatsoever. Maximum torque under steady, non-accleration enriched conditions is about 13.2:1. Maximum transient enrichments with the engine warm are about 12.5:1. On RSR Fuel Injection system we program the maps to reflect these issues on higher load conditions. You have a programmable accelerator pump and you have the fuel map. When you "nail" the throttle and go past 50% throttle opening our system goes out of closed loop and operates on the higher load base map and the attendant modifiers...but not the O2 sensor! With our RSR Air Fuel Ratio Gauge you simply tune to two of the ten lights (2nd Orange / First Red) to get these ratios at w.o.t. One or two readings at peak and lesser rpms is all that is needed. Let Autocal.V6 redraw your base map.

5. Closed Loop Tuning: We tune in closed loop...everything from idle to full throttle (where it goes out of closed loop). We often target the idle to be a bit richer than 14.7:1 and let the computer take out 10%. For cruising we, for the most part, let the computer add fuel by programming below stoichiometry, often adding 15%. This may not be what you expected nor what some guru is going to tell you but it is the correct way to do things. Think about it...You sure can't run the bike around with it running 15% leaner than it is supposed to be unless you do it under closed loop.

6. Conundrum: You are at sea level on a cold dense air day and your bike is tuned to run like a bandit. Next day you are in Denver kissing 10,000 feet on a hot, no-air, day with the same calibration, be it carburetor or efi. Guess what is going to happen. No power. Think about it...what good does it do to tune in Open Loop where the bike won't even run unless its generally on the rich side...and then flip it into closed loop. What is the spread in fuel requirements and can your ECU auto-correct for these extremes? The RSR Closed Loop Fuel Injection can. Tune in Closed Loop.

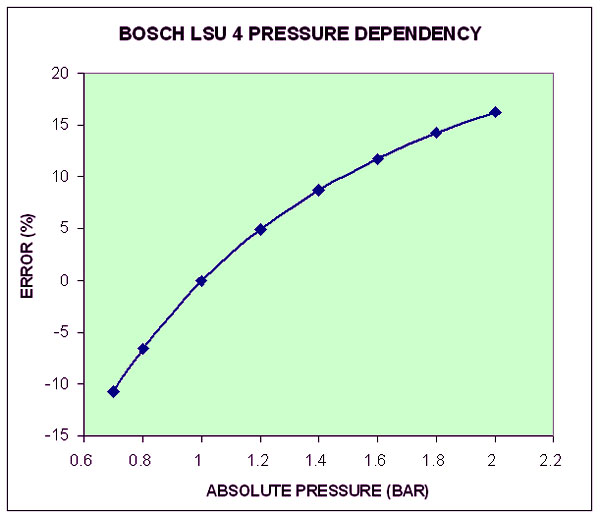

Why EGT and Narrowband.... Not Wideband for Turbos

As you can see from the chart a Bosch LSU 4 wideband sensor has a 15% error if subjected to 2 Bar exhaust pressure. On turbos you have to mount a wideband sensor after the turbo which is a big problem because turbos, at least in race applications, use short dump tubes and this is way too close to oxygen-rich atmospheric air. On our race bikes we use our RSR Air Fuel Ratio Gauge which is not affected by exhaust pressure. On our Bonneville Bullett we run two single wire high temperature Bosch O2 sensors in addition to the dual egt ORCA Turbo Dash. Wideband LSU 4 sensors can be damaged with egts greater than 1500 Deg F. We run above this.

A second reason you use egt on turbos is that, if you are running leaded race gas, any O2 sensor, narrow or wideband, will become contaminated, resulting in false readings. This can happen very quickly or maybe 10 hours later depending on the fuel used. When fouled, they render false lean readings. It is better to watch and record high egt temperatures which are completely unaffected by either pressure or racing fuels.

Check out our ORCA Turbo Dash for specialized turbocharger and supercharger applications. Used in conjunction with our RSR Air Fuel Ratio Meters these are the best way to tune and monitor your high horsepower application.

What is Your Tuning Strategy?

Closed Loop and Open Loop are different animals when it comes to strategy. If Open Loop, you must tune to a narrow range in terms of air-fuel ratios...below 14.7:1 it gets a bit dicey, except on high-speed decel, and beyond certain ratios, about 12.5:1 it's just too rich. Temperatures figure in where, if it's really cold, the ratios can be 50% greater on cold start.

In Closed Loop the O2 sensor tries to run a rich-lean scenario where it averages out at about 14.7:1. In Closed Loop you do not program for a target of 14.7:1 no matter what someone tells you! The fuel map in closed loop is a complicated target area where your baseline (before correction) figures vary in different load/rpm sites. Anyone who tells you their system "self tunes" only means they have simplistically set target ratios. The scenario gets more complicated as the loads increase because, at wide open throttle, and quite a bit before this happens, the system should not be in Closed Loop at all! O2 correction or Closed Loop operation is not compatible with higher load or wide open throttle situations.

Keep in mind that your base map has to be correct...then the O2 sensor takes over! Also, keep in mind that high load or wide open throttle has nothing to do with Closed Loop operation.

Infinite Stock EFi Problems

Some people will have you replace your sophisticated new Delphi controller with their controller and let your bike auto-tune itself...This does not change the base map at all, it only filters it through throttle angle/rpm intersects that modify the base map signal. If you want to see what's going on and try to tune it manually they tell you you have to do this in open loop. Well, if the base map is correct for sophisticated closed loop running, you can't do this in open loop because you need portions of the map below 14.7: or the 13:1 they tell you to do, so the computer can add fuel sometimes but not subtract all the time.

It sure gets complicated. We addressed these problems a long, long, time ago. You have to tune in closed loop and you have to have the base map correct.

The reason people go switching their perfectly good OEM Delphi ECU is that they do not know, or their mechanic does not know how to tune efi. Everyone wants to open the box, push the majic button and find happiness. They find worse mileage than stock when they are finished.

We elected to stay out of the stock replacement business and concentrate on the best solution both airflow/mechanical as well as from a software/tuning strategy. This is why we came up with Autocal.V6

All Your Base Belong to Us

RB Racing's Autocal.V6 software takes this into consideration and writes a base map for you automatically as well as pre-setting hundreds of other modifiers that are not exactly easy to understand. Regions of the fuel map are written to different base map target figures for Closed Loop operation.

Most importantly, if you want 132 hp worth of fuel @ 6400 rpm, Autocal.V6 will do this for you perfectly with absolutely zero testing! No dyno, no guru, no authorized, trained, technician.

No Dyno, No Technician, No Tuning Center, Just Results

We don't want you to get on your knees and get out your KY Jelly and report to the dyno room. With the RSR EFi you simply get the bike running, observe the RSR Air Fuel Gauge and make logical changes with the Autocal.V6 Professional Software. By knowing if something is rich or lean at some point you can alter hundreds of points without entering any numbers whatsoever. If you need more horsepower you just put in a bigger horsepower number. If you change cams and you need to alter the power curve you just change the shape of the curve and hundreds of changes are made.

You don't beat your bike to death on the dyno where the poor fool is pounding in numbers he will never remember. Forget the fucking numbers...just observe things and make intelligent moves. Ride your bike in the real world and tune it for that world.

You do not need anyone to help you. We give you the power to do it yourself...and better.

First Fuel Injected Harleys in the 9's, 8's and 7's

We've been at this for awhile from our early 80's 150hp Shovelheads up through our specialized 300+hp Turbo ORCAS. We put the first fuel injected Harleys into the 9's, 8's and 7's at the drag strip and are looking to put one into the sixes in the near future. The only fuel injected intercooled Harleys that hold national drag racing championships or Bonneville records come from one place..RB Racing. RSR Fuel Injection, the only race proven fuel injection system.

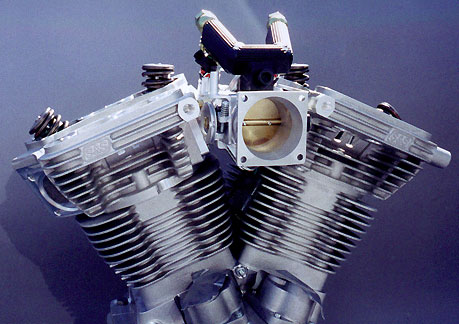

To Butterfly or Butterflies, that is the Question

We answered this thirteen years ago...and the answer is "butterfly" not "butterflies". Two butterfly inlets with their separate inlet tracts might be the path to trying to isolate injection events for emission purposes, but it sure is a lousy way to flow air. In case you haven't thought about it, your inlet ports face each other with an inlet volume smaller than a tennis ball. With the ports facing each other at a 60 degree angle in an 45 degree V-Twin, there simply is not enough room for two large inlet tracts to fit in this space without some kinky sharp radius turns. Airflow does not like to turn which is why XR750s run with two "front" heads. Trying to get two inlet tracts into an EVO or TC88 is patently stupid. When the engineers look at the staggered inlet events and the wild inlet fluctuations they run for their mother's twin butterfly bosoms to solve their "predictability" problems. In their flight from uncertainly they left the baby named "performance" out in the cold.

RB Racing faced these issues, solved the technical problems and gave birth to a 56mm (2 3/16") single butterfly that does not limit your potential. We make these for normally aspirated and turbocharger applications. The turbo applications are spigot mount via a 2.5" i.d. silicone turbo hose to our inlet plenum chamber. Normally aspirated models employ a four bolt mount to a billet backing plate.

Thorny problems often lean to compromises...We decided not to compromise. No compromise on airflow. End case.

No tricky oval bores.Our cross sectional area a flow rate exceeds the inlet capability of any inlet port flow.

We also designed our fuel injector placement so they do not spray directly on the inlet valves. Car guys figured that one out a long time ago. Check around. We can place up to two 2000cc injectors to fuel your engine.

Flexibility, No Dead Ends

Don't be fooled by other "fuel injections" with promises of "plug and play" and that they are easy to use and offer all sorts of "tunability." Most people can't tune carbs and they won't fare any better with efi. Flexibility is the key because every application is different. Only RSR fuel injections can be configured for .5, .75, 1, 2, or 3 Bar operation. Only RSR Fuel Injections can run 2 or four injectors (actually up to 32). Only RSR Fuel Injections can run configured as a primary / secondary injector system.

Only RSR Fuel Injections have the capability to run multi-fuel strategies as well as different size injectors within the same application. Only RSR Fuel Injections are true Closed Loop oxygen sensing systems for maximum self-regulating economy. Only RSR Fuel Injection systems have true computer controlled idle air control motors. We could go on with this, but we suggest you do your homework and choose the manufacturer who has vertical solutions to your particular needs...only RB Racing manufactures the injection system, the exhaust system and the turbo system in an integrated package.

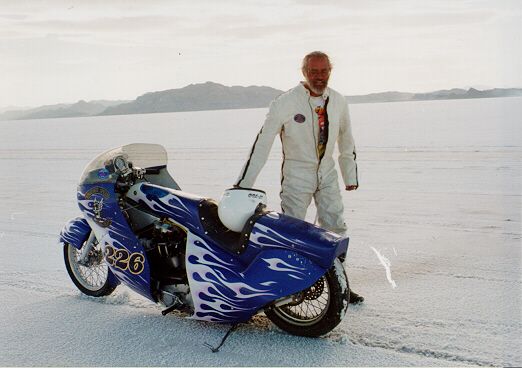

200 mph Proven. Drag Strip Proven. Harley-proof!

Six years of racing at the Bonneville Salt Flats and El Mirage / Muroc Dry Lakes have put six RSR Fuel Injected Bikes into the prestigious 200 MPH Club. Over 1,000,000 road miles, with individual Big Twins going 30,000+ miles averaging 45-55 mpg, has proven the RSR Fuel Injection to be both reliable and superb in it's operation. Stock Sportsters to 140 c.i. supercharged Big Twins and everthing in-between, you name it, and RSR fuel injection has "been there, done that".

Mike Geokan's Bonneville Record holding bike. Mike is not yet on a salt free diet and his RSR 400i Fuel Injection System has got him into the record books, numerous 1st place in customs shows and a whole bunch of looks when he takes the "Blue Bike" cruising the streets of Boise. Mike wanted a 200 mph street bike and he got it. His bike has had an RSR 400i Fuel Injection for 10 years.

Ken Browne's RB Racing Pro Gas Turbo holds the #1 Plate in the AHDRA Pro Gas Class. Ken uses our RSR 400i Fuel Injection System and Pro Gas Turbo to tear up the quarter mile in 7.55 seconds @ 176mph! The fuel injection completely eliminates fueling problems and lets Ken concentrate on the clutch management and the driving.

Click on photo to enlarge

Clean Rock Solid Installation

All RSR Fuel Injections come pre-programmed for your application whether it be a stock 74" Sportster or a 96" Big Twin. Each unit is shipped 100% complete, including serial communicatons software. If you change cams, exhausts, or even displacement your RSR "Black Box" (Electronic Control Unit) can be reprogrammed in minutes with the Autocal Software.

RSR Fuel Injections are available as two injector (RSR 200i). The base RSR 200i system is available in different ratings up to 400 + horsepower . For use with very high flow situations involving methanol our RSR 400i will support in excess of 500 hp and is available with special injectors up to 2000cc/min.

It's the airfow, stupid.

Your big twin is an air pump and its power is strictly limited to the amount of air it can pump in a unit of time whether you measure it in cubic feet per minute (cfm) or pounds per hour (lb/hr). A carburetor has to be sized to match the engine displacement...If it is too big it won't pick up the fuel at lower speeds ...and if it is too small your peak horsepower will be limited.

\On RSR digital electronic fuel injections you don't have to worry about low speed fuel delivery as the fuel pump and injectors will deliver a high pressure atomized burst of fuel at any rpm...all the butterfly does is meter air. The fuel is directly injected into each inlet port for instant response and perfect fuel distribution. To insure your motor gets all the air it needs we use a 2 3/16" Throttle Body (56mm) which gives you limitless top end power. Your peak airflow will be determined by your cylinder head design and not by the RSR efi Throttle Body! If you port your heads, put in monster valves, mega-lift cams , and bump the compression into the stratosphere the RSR 2 3/16" diameter bore, measured at the butterfly, will not be a restriction in your top end design. Sportster 56mm throttle body pictured, set up with RSR 200i 120 hp injectors.

Reliability, reliability, reliability

Long lonely stretches of highway, cold nights where you keep banging your hands on your knees to see if either one of them is alive...and the RSR Fuel Injection is closed-looping you to 55mpg to that truck stop where you can thaw out, that is if you can get off the bike without falling over. Been there, done that. You can count on the RSR Fuel Injection not to fail. More than fifteen years of testing and a collection of the finest components won't let you down. Your modern car has fuel injection and you don't give it a second thought...and you shoudn't with your Harley either.

To this end we use fully encapsulated (3 different compounds) electronics, waterproof enclosures and wiring and only the best components in the world, like Bosch, General Motors, Delphi, Ford,Visteon and RC Racing (fuel injectors).All critical components: ECU, fuel pump, and injectors are fused with standard General Motors fuses. In ten years we have seen everything fail on Harleys, only it hasn't been any of our components. Only military spec electronics are used to ensure reliability in harsh conditions. You get the idea, we've done everything to make sure the system will never let you down. Never is a long, long, time but in our short pitiful existence you can forget about reliability concerns.

Click on photo to enlarge

What comes in the RSR EFI package?

Look at the picture. Holy shit, what a bunch of stuff! Go look at the various bikes in our web site and you'll see all that stuff disappears.Check out the links to: LSR 2-1 Pro Stock, RB Harley Turbos, or LSR Mega Megs and you'll see most of the stuff simply vanishes. The RSR ECU mounts underneath the steering neck where it stays cool and is easily accessible for reprogramming. We mount the MAP Sensor (manifold absolute pressure sensor) right beneath the ECU where you can easily get to it if it has to be replaced...it's a standard GM Part available at any auto parts store.

The wiring harness is automotive grade 350 degree F/ solvent resistant wiring covered in a fiberglass protective (against abraision) sheathing. All connectors are silicone sealed and waterproof. Even the fuel pump and filter are mounted for cool, reliable operation and easy access. Jesus, Harleys are tough things to design parts for! The air filter is genuine K&N, 8" in diameter and will flow enough air even on high output big inch motors. You get all the damn hardware like fuel pump, fuel filter, gas tank quick release return port, inlet mainfold, throttle body,fuel rail, injectors, air temp sensor, oil temp sensor, O2 sensor, TPS sensor, MAP sensor, Idle Air Control Motor, air cleaner assembly, fuel lines and fittings,fuel pressure regulator, Autocal User Software, tuning cable (PC to ECU), a bunch of instructions, and a box to bury your carburetor in.

Tuning RSR EFI Systems...No "Magic Downloads"

You write your own ECU calibration. You don't crawl around websites begging for someone's magic fuel map. In a few minutes with Autocal.V6 you can write an entire ECU calbration for any injector size, any fuel pressure, any horsepower or whatever. When you buy the RSR EFi you are self-contained, with no need for tuners or dyno time.

People really just want the answers. Who the hell wants to learn anymore. Me! Me! Me! Now! Now! Now! The new reality. Fame fortune lights! Next Please.

We give you simplicity and power...If that's not enough then you should take up some other activity where you can spend your time asking others for answers, or just look in the mirror and see the tuner. Eureka!

Your RSR Fuel Injection will come pre-programmed

for your specific application. We need to know a few simple

facts about your motor: cubic inches, compression ratio,

expected peak horsepower, peak rpm, and some idea about your

camshaft/cylinder head set-up. We do the pre-programming with

our Autocal Professional Software which allows us to get you up

and running quickly no matter what your engine set-up is. Go to

the Autocal section to read about the Professional edition of the

software or read more on tuning in our About RSR section.

Your RSR EFI System comes with free software (DOS: Win 3.1/95/98..NOT 98SE/2000) for both direct to the ECU as well as off-line programming as well as a serial cable to connect your RSR ECU to your PC which allows both real time editing as well as loading in new programs. RSR ECUs cannot "lose" their memory...If you disconnect your battery, all programs in the ECU remain unaffected.

The IBM Laptop sent with your system contain files

that can be reloaded if you just want to get back to where you

started from. All editing you do can be recorded and stored in

the Autocal file system for future reference or analysis. All

tuning should be done with the RSR Air/Fuel Ratio Meter as

it is the only way to know in real time what your motor is

doing. The meter remains permanently mounted to your bike and is

unaffected by rain or temperature extremes and is visible in

direct sunlight and also dims at night so as not to be too

bright.

The RSR Air/Fuel Ratio Meter gets feedback from a Bosch Oxygen Sensor mounted in your exhaust system. All RB Racing LSR Exhausts already have O-Sensor ports heliarced in the front primary tube. See LSR 2-1, LSR 2-1 Pro Stock, for color pictures of these systems. You will have to install (weld) the provided O-Sensor port to your existing exhaust if you don't have one.

Responsibility

A word about "responsibility", which is

definitely something you should look up the meaning to when it

comes to fuel injection. If you are not prepared to take the

time to learn how it operates, to hook it up as we suggest, or

to insure your work is done in a logical, clean and

professional manner, then forget about fuel injection. Poor

electrical systems, too much compression for reliable

starting, shoddy wiring, gas tanks full of rust or sand, tired

batteries, faulty charging systems etc all conspire to doom

fuel injection.

If you aren't prepared to learn how to tune it yourself then don't buy it...because you will be trying to transfer the responsibility to some other hapless mechanic who isn't full of your enthusiasm. As we say...get up in the morning, look into the mirror...there's the tuner.

Voodoo Tuning

There's a huge difference between knowing what's going to happen and just doing something to see what happens. The difference is that you have to think in advance in the former and think afterwards in the latter. With Autocal.V6 Professional Software you do your thinking ahead of time. If you don't want to take this approach you probably should skip fuel injection altogether because you have hundreds of digital decisions to make and they are all, for the most part, interrelated.

Voodoo tuning is where you want to find your Messiah, the Prophet, the Oracle....or the guy who has something that works so you can copy it and find bliss. You don't want to think, you just want what "he has". Every case is unique and since you are only concerned with "your case", you'd better think about your situation and forget about the others...the magic file does not exist unless you do it yourself. There are a lot of false prophets. Take your own path. Find the truth yourself and tell others they must find their own way. There is no elevator to the mountain top.

Recommended Procedure and Comments

1. Don't put the efi on any motor that hasn't been run. If it's a new engine, break it in with a carburetor first. Fix all the damn problems before you put on the efi.

2. Use compression releases either S&S

electric, or the push-button chainsaw variety. If you don't do

this, especially on built, high-compression, motors there will

be voltage drops during cranking that will simply not work

with any efi system. Any drops in voltage below 11VDc during

cranking will cause the fuel pump to stop working as it takes

a lot of amps to keep the system at 55psi. No fuel and the

bike won't run. Many bikes drop to between 8 and 4 VDc during

cranking, especially if the battery is a bit tired. If you

have a fresh battery and compression releases you won't have a

problem. Good idea to buy a trickle charger. Li-Ion battery

should be installed to maintain 13VDC.

You must use a 32/38 or 40 amp charging system. Either a manual switch or relay cut out of the headlight during the cranking phase.

3. Mount the system as we ask you to and don't attempt to hide things like the ecu beneath seats, gas tanks and the like as you will only cause problems. Heat, length of vacuum lines, routing of the efi wiring harness to avoid strain on connectors etc. are all very, very important.

4. There are a lot of ignition systems on the market...not all of which will trigger our efi box. If your wazoo ignition doesn't run our efi then change your ignition, don't complain to us. Major brands such as Dayton Twin Tec, DYNA, and Crane seem to work OK. Our efi has to see a dedicated tach signal with one pulse per crank revolution. Even "noisy" coil negative signals from a distributor will trigger our ecu, but not millivolt, extremely short, duration signals that some ignitions put out. Lousy crimp on connectors, non-automotive grade wire, lack of waterproofing all will bite you. Skip the crap, use well made components.

5. Don't think you will "drop the bike off" at some dyno shop for them to tune it. They won't be familiar with the system and the dyno is very hard on an air cooled engine, not to mention the loads do not agree with the real world. Get the bike to idle, start and take throttle and ride it to evaluate what decisions have to be made. Simple peeks at the RSR Air Fuel Ratio gauge at various rpm/load points (only a few) will tell you what changes have to be made.

6. Except for race bikes, all tuning should be done with unleaded pump gas in closed-loop. Tuning in open-loop will result ultimately in "too rich" fuel maps. Much of the "map" should be programmed at leaner mixtures than the bike will operate in...this is a difficult concept for people to accept.

7. For those of you that think tuning an efi system is going to be easy because you "know computers"...you are dead wrong. If you are a tuner and can think logically you will be in Hog Heaven. If yelling at other people to get your "way" is your methodology, they bypass the efi game and head directly to the door marked "Brass Jets".